Part 1: Fundamentals of Heat Sinks in New Energy Vehicles and CNC Machining

1.1 Role of Heat Sinks in New Energy Vehicle

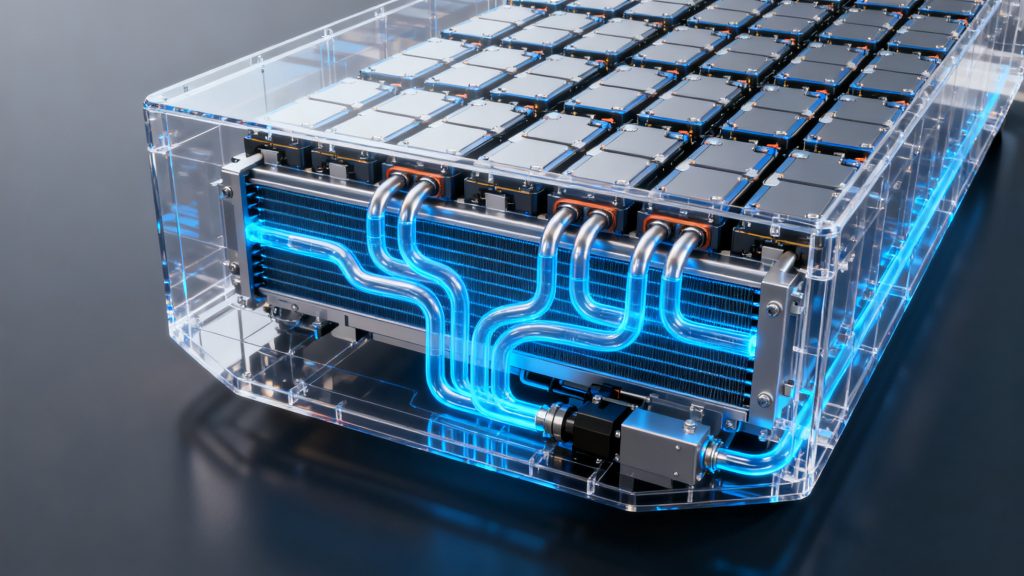

New energy vehicles (NEVs)—including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs)—depend on thermal management systems to maintain the stability of core components, and heat sinks are the “thermal guardians” of these systems. Key heat-generating components such as lithium-ion battery packs, power inverters, and motor controllers produce significant heat during operation: a typical BEV battery pack can reach 50–60°C under high-load driving (e.g., rapid acceleration or climbing), while IGBT modules in inverters may exceed 120°C. Overheating directly impairs performance: lithium-ion batteries operating above 45°C lose 20–30% of their capacity over 1,000 charge-discharge cycles, and power electronics may trigger thermal shutdowns, disrupting driving.

Effective heat dissipation via heat sinks directly boosts energy efficiency. For example, Tesla’s Model 3 uses customized heat sinks to keep its battery pack within the optimal 25–40°C range, enabling the battery to maintain 90% of its discharge efficiency—translating to a 5–8% increase in real-world driving range (from 440 km to 475 km under the same battery capacity). Similarly, heat sinks for motor controllers reduce energy loss caused by thermal resistance, ensuring the motor converts electrical energy to mechanical energy at an efficiency of over 95%, compared to 90% for poorly cooled systems.

1.2 Introduction to CNC-machined Heat Sinks

CNC (Computer Numerical Control) machining is a precision manufacturing process that uses pre-programmed software to control machine tools (e.g., mills, lathes, and routers), enabling automated, high-accuracy fabrication of complex parts. For heat sinks, CNC machining typically involves three core steps: first, importing 3D CAD models of the heat sink into CNC software (e.g., Mastercam or Siemens NX); second, optimizing tool paths to minimize material waste and machining time; and third, using high-speed spindles (10,000–20,000 rpm) to shape the base material into the desired heat sink structure.

The advantages of CNC-machined heat sinks are tailored to NEV needs. First, high precision: CNC machining achieves dimensional tolerances of ±0.01–0.05 mm, ensuring heat sinks fit perfectly with NEV components (e.g., battery cell gaps or IGBT module mounting holes), reducing thermal resistance at the contact interface. Second, complex geometry capabilities: unlike traditional extrusion (which is limited to straight fins), CNC machining can create micro-fins (0.3–0.8 mm spacing), pin fins (variable diameters), or offset strip fins—designs that maximize surface area for heat transfer. For example, a CNC-machined micro-fin heat sink has 30–50% more surface area than an extruded counterpart of the same size. Third, repeatability: CNC systems maintain consistent quality across thousands of units, critical for NEV mass production (e.g., 100,000+ heat sinks per year for a popular BEV model).

1.3 Compatibility of CNC-machined Heat Sinks with NEV Components

CNC machining’s customizability ensures seamless compatibility with diverse NEV components, addressing the “one-size-fits-none” challenge of traditional heat sinks.

For battery packs, compatibility starts with form-factor matching: CNC-machined heat sinks can be tailored to square (e.g., BYD Blade Battery), cylindrical (e.g., Tesla 4680 cells), or pouch (e.g., Hyundai E-GMP) battery designs. For example, a CNC-machined heat sink for cylindrical cells features semi-circular grooves that wrap around each cell (diameter 46 mm for 4680 cells), ensuring direct thermal contact—this design reduces thermal resistance by 25% compared to flat heat sinks. Additionally, CNC machining can integrate cooling channels into the heat sink base (e.g., 2–3 mm diameter water channels), enabling hybrid cooling (conduction + liquid cooling) for high-capacity battery packs (100 kWh+).

For power electronics (inverters, chargers), CNC-machined heat sinks are designed to match the compact form factors of these components. For instance, a heat sink for a 200 kW inverter has a stepped structure that fits around the inverter’s capacitor bank and IGBT modules, with dedicated fin arrays above each heat-generating component. This targeted design ensures the IGBT module (the hottest spot) receives 40% more cooling capacity than other areas, preventing localized overheating.

Part 2: Optimization of Energy Use by CNC-machined Heat Sinks in NEVs

2.1 Heat Transfer Optimization

Efficient heat transfer is the core of energy optimization, and CNC machining enhances this through advanced fin designs and material optimization.

Enhanced fin designs directly boost heat dissipation efficiency. Micro-fins (spacing 0.5–1 mm, height 5–10 mm) are a hallmark of CNC machining: their narrow spacing increases surface area density (up to 500 cm²/cm³) while promoting laminar airflow, which reduces thermal resistance by 15–20% compared to standard fins. For example, Volkswagen’s ID.4 uses CNC-machined micro-fin heat sinks for its battery pack, reducing the pack’s average temperature by 8°C during fast charging, cutting charging time by 10% (from 45 minutes to 40 minutes for 10–80% charge). Pin fins, another CNC-enabled design, excel in liquid-cooled systems: their cylindrical shape creates turbulent flow in cooling fluids, improving heat transfer coefficient by 25–30% compared to straight fins. This is critical for motor controllers, where pin-fin heat sinks reduce the need for high-flow-rate pumps, lowering pump energy consumption by 12–15%.

Material selection and optimization further amplify heat transfer. Aluminum (e.g., 6061, 6063) is the most common material for CNC-machined heat sinks, with a thermal conductivity of 201–230 W/(m·K) and excellent machinability—CNC mills can shape aluminum into complex fins 30% faster than copper, reducing manufacturing energy use. For high-heat components (e.g., 800V motor controllers), copper (thermal conductivity 401 W/(m·K)) is preferred; CNC machining addresses copper’s high hardness by using carbide tools, enabling the creation of thin-walled fins (0.5 mm thickness) that balance heat transfer and weight. Additionally, CNC machining allows post-processing (e.g., anodization), which forms a 5–10 μm oxide layer on aluminum heat sinks—this layer improves corrosion resistance without compromising thermal conductivity, extending the heat sink’s lifespan and reducing replacement-related energy costs.

2.2 Energy-Saving in the Manufacturing Process

CNC machining reduces energy consumption not only in NEV operation but also in heat sink production, aligning with sustainable manufacturing goals.

Precision machining minimizes material waste, which in turn cuts energy use for raw material production. Traditional heat sink manufacturing (e.g., casting or extrusion) generates 15–20% material waste, while CNC machining reduces this to 5–8% by optimizing tool paths to “nest” heat sink designs within the raw material block. For example, machining 1,000 aluminum heat sinks (each weighing 200 g) via CNC produces only 8–16 kg of waste, compared to 30–40 kg for extrusion. Since aluminum production requires 155 MJ/kg of energy, this waste reduction saves 2,170–3,720 MJ per 1,000 heat sinks—equivalent to the energy needed to power a BEV for 800–1,400 km.

Efficient production processes lower machining energy use. CNC machines feature variable-speed spindles and energy-saving drives that adjust power consumption based on workload: during low-load operations (e.g., finishing cuts), spindle power drops from 5 kW to 1.5 kW, reducing energy use by 70%. Tool path optimization (e.g., using “high-speed machining” strategies) also cuts machining time by 20–25%: a heat sink that takes 10 minutes to machine with a traditional path takes only 7.5–8 minutes with an optimized path, reducing energy consumption per unit by 20%. For a factory producing 500,000 heat sinks annually, this translates to 120,000–150,000 kWh in energy savings—enough to power 40–50 average households for a year.

2.3 Integration with Vehicle-wide Thermal Management

CNC-machined heat sinks do not operate in isolation; their integration into NEVs’ smart thermal management systems (STMS) multiplies energy optimization effects.

Smart thermal management systems leverage CNC heat sinks’ adaptability to adjust cooling in real time. STMS uses temperature sensors (embedded in battery packs and power electronics) to monitor heat levels and adjust cooling intensity: when the battery temperature is below 25°C (e.g., cold weather), the system reduces airflow over the heat sink or slows the liquid pump, cutting cooling energy use by 30–40%. When the battery exceeds 40°C (e.g., fast charging), the system increases cooling, with CNC-machined heat sinks’ high heat capacity ensuring rapid temperature reduction without overcooling. For example, Ford’s Mustang Mach-E uses this strategy, reducing the thermal management system’s energy consumption by 18% in urban driving, adding 12–15 km to its range.

Synergy with other cooling components enhances overall system efficiency. CNC-machined heat sinks are designed to complement fans, liquid coolers, and heat exchangers: for instance, a heat sink for the battery pack features a flat base that mates with a liquid-cooling plate, with fins aligned to the direction of fan airflow. This alignment reduces airflow resistance by 10–15%, allowing the fan to operate at a lower speed (2,000 rpm vs. 2,500 rpm), cutting fan energy use by 25%. In liquid-cooled systems, CNC-machined heat sinks have uniform internal flow channels that prevent coolant stagnation, ensuring the heat exchanger operates at 90% efficiency (vs. 80% for poorly designed heat sinks), reducing the load on the vehicle’s cooling loop.

2.4 Long-term Energy Savings and Cost-effectiveness

The value of CNC-machined heat sinks extends beyond immediate energy gains, delivering long-term savings through extended component lifespan and favorable ROI.

Extended component lifespan reduces replacement-related energy and cost. Effective heat dissipation slows component degradation: a battery pack cooled by CNC-machined heat sinks retains 80% of its capacity after 1,500 charge-discharge cycles, compared to 80% retention after 1,000 cycles for poorly cooled packs. This extends the battery’s lifespan from 8 years to 12 years, avoiding the energy-intensive process of battery replacement (producing a 75 kWh battery requires 17,000–20,000 MJ of energy). Similarly, power electronics cooled by CNC heat sinks have a lifespan of 10 years vs. 7 years for unoptimized systems, reducing the need for manufacturing and installing new components.

Favorable ROI justifies initial investment. While CNC-machined heat sinks cost 15–20% more upfront than extruded heat sinks (e.g., $25 vs. $21 per unit), the long-term savings offset this: a BEV with CNC heat sinks saves 200–300 kWh of energy annually (via improved battery efficiency and lower cooling 能耗), translating to $25–$35 in electricity savings per year (at $0.12/kWh). Over the vehicle’s 10-year lifespan, this totals $250–$350 in energy savings, plus $500–$800 in avoided battery maintenance costs. Most车企 recover the initial cost of CNC heat sinks within 3–4 years, with net savings of $400–$900 over the vehicle’s lifetime.

FAQs (Frequently Asked Questions)

1. Are CNC-machined heat sinks more expensive than other types of heat sinks?

Initially, yes—CNC-machined heat sinks cost 15–20% more than extruded or cast alternatives due to precision equipment and longer machining time. However, their long-term value outweighs this: they reduce NEV energy use by 5–8% annually, extend battery lifespan by 40%, and lower maintenance costs. As CNC technology scales (e.g., automated production lines), costs are falling—some manufacturers now offer CNC heat sinks at a 10% premium, with ROI periods under 3 years.

2. How do CNC-machined heat sinks adapt to different operating conditions in NEVs?

CNC machining enables design flexibility for diverse conditions: in hot climates (e.g., Arizona), heat sinks use wide-spaced fins (1–1.2 mm) to avoid dust clogging and enhance airflow; in cold climates (e.g., Canada), they integrate heating elements into the base (machined via CNC) to pre-warm the battery. Smart thermal management systems further adapt performance—adjusting fan speed or coolant flow based on real-time temperature data—to ensure optimal cooling regardless of driving load or weather.

3. Can CNC-machined heat sinks be recycled?

Yes, most CNC-machined heat sinks are made of aluminum or copper, which are 100% recyclable. CNC machining’s precision also simplifies disassembly: heat sinks have standardized mounting holes (machined to ±0.05 mm), making them easy to remove from retired NEVs. Recycling aluminum heat sinks requires 95% less energy than producing new aluminum, while recycled copper retains 90% of its thermal conductivity—aligning with NEVs’ sustainability goals.

LSI and NLP Keywords and Related Vocabulary

LSI Keywords

CNC-machined heat sinks for new energy vehicle thermal managementEnergy optimization by CNC-made heat sinks in EVsHeat transfer improvement with CNC-machined heat sinks in new energy carsManufacturing energy savings of CNC-machined heat sinks for new energy vehiclesLong-term energy savings with CNC-machined heat sinks in EVs

NLP Keywords

CNC-machined heat sinks and new energy vehicle energy efficiencyOptimizing energy use with CNC-manufactured heat sinks in electric carsRole of CNC-machined heat sinks in vehicle-wide thermal managementCost-effective energy optimization using CNC-machined heat sinks in new energy vehicles

Related Vocabulary

New energy vehicles (electric vehicles, hybrid vehicles), thermal management, heat transfer, heat sink materials (aluminum, copper), fin design (micro-fins, pin fins), precision machining, material waste, smart thermal management, component lifespan, recycling, energy efficiency, manufacturing costs, IGBT modules, lithium-ion battery packs, thermal resistance, heat exchanger