Part 1: Introduction to CNC-milled Carbon Fiber Parts and eVTOL Aircraft (800 words)

1.1 Basics of eVTOL Aircraft (300 words)

eVTOL (Electric Vertical Take-Off and Landing) aircraft represent a transformative segment of urban air mobility (UAM), combining helicopter-like vertical lift with fixed-wing efficiency—all powered by electric motors and battery packs. Unlike traditional helicopters, eVTOLs rely on distributed propulsion systems (e.g., multiple rotors or ducted fans) to enable quiet, low-emission flight, making them ideal for short-range applications: urban commuting (e.g., 10–50 km trips between city centers), emergency medical transport (delivering supplies to remote areas), and cargo delivery (last-mile logistics for e-commerce). Leading models like Joby Aviation’s S4 and EHang’s EH216-S have already completed thousands of test flights, with commercial operations expected to launch in major cities by 2025–2030.

eVTOL design faces unique challenges, most critical being weight sensitivity: every kilogram of excess weight reduces battery range by 5–8 km (per industry tests), as batteries account for 40–60% of an eVTOL’s total mass. Additionally, components must withstand extreme aerodynamic forces—during vertical take-off, rotors generate lift loads up to 12G, while transition to forward flight creates sudden stress on the airframe. Safety is non-negotiable: eVTOLs require fail-safe structures to meet aviation regulations (e.g., FAA’s Part 21.1309), demanding materials that balance lightness, strength, and durability. Traditional metals like aluminum and steel struggle to meet these demands, creating a gap that carbon fiber components fill.

1.2 Overview of CNC-milled Carbon Fiber Parts (300 words)

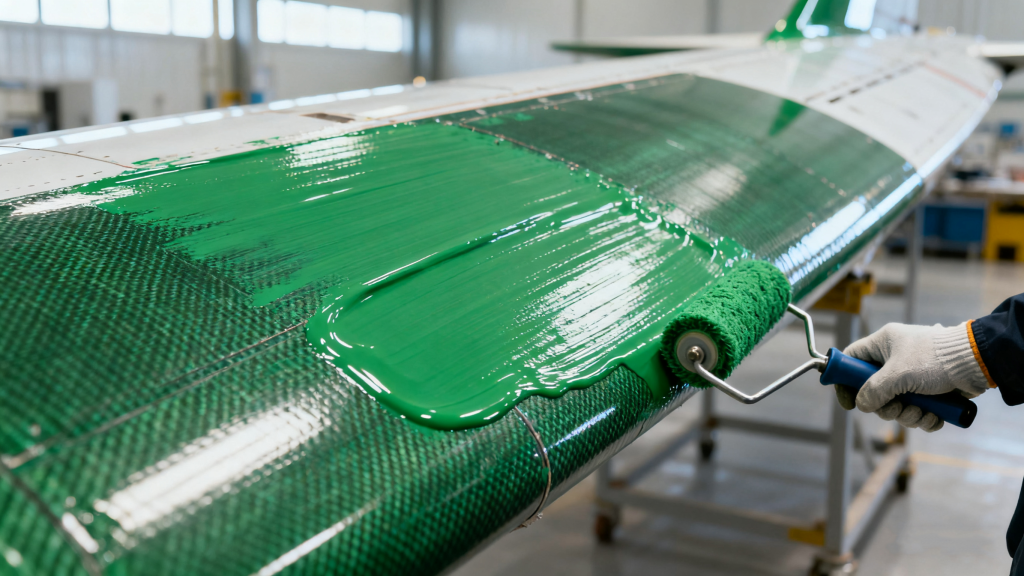

Carbon fiber composites—made of carbon fiber strands embedded in a polymer matrix (e.g., epoxy)—offer properties that outperform traditional aircraft materials. Their strength-to-weight ratio is 5x higher than steel (tensile strength: 3,000 MPa vs. steel’s 600 MPa) and 2x higher than aluminum, while their stiffness is 3x greater than aluminum (Young’s modulus: 230 GPa vs. aluminum’s 70 GPa). They are also corrosion-resistant (no rusting like steel) and fatigue-resistant (maintaining strength after 10,000+ stress cycles), addressing key eVTOL pain points.

CNC milling transforms these materials into precision parts via a three-step process: first, 3D CAD models of the part (e.g., wing spars or rotor hubs) are imported into CNC software (e.g., Siemens NX or Autodesk Fusion 360); second, tool paths are optimized to minimize fiber fraying (a common issue with carbon fiber) using high-speed, carbide-tipped end mills (15,000–30,000 rpm); third, the CNC machine shapes the carbon fiber blank—either a pre-cured composite panel or near-net-shape mold—with tolerances as tight as ±0.01–0.05 mm.

This process offers three irreplaceable advantages for eVTOLs: precision (critical for mating components like rotor mounts), repeatability (consistent quality across 100+ units for mass production), and complexity (ability to create integrated geometries—e.g., hollow winglets with internal ribs—that reduce part count and weight).

1.3 Initial Attraction of CNC-milled Carbon Fiber Parts to eVTOL Aircraft (200 words)

The primary appeal of CNC-milled carbon fiber parts lies in their ability to solve eVTOLs’ most pressing challenge: weight reduction. For example, a CNC-milled carbon fiber wing spar for a 5-seat eVTOL weighs 2.8 kg, compared to 6.2 kg for an aluminum equivalent—a 55% weight savings. This translates directly to extended range: Joby Aviation reports that replacing 10 key aluminum components with CNC-milled carbon fiber parts increased the S4 eVTOL’s range from 160 km to 240 km, a 50% improvement.

Design flexibility further drives adoption. eVTOLs require non-traditional shapes (e.g., curved fuselages to reduce drag, asymmetrical rotor arms for stability) that are difficult to achieve with metal machining. CNC milling allows manufacturers to integrate features like cable channels or mounting brackets directly into carbon fiber parts—eliminating 5–10 separate components per assembly and reducing assembly time by 30%. For instance, EHang’s EH216-S uses a single CNC-milled carbon fiber fuselage section instead of 12 aluminum parts, cutting weight and simplifying maintenance.

Part 2: In-depth Reasons for the Popularity of CNC-milled Carbon Fiber Parts in eVTOL Aircraft (1200 words)

2.1 Structural Performance and Safety (400 words)

eVTOLs operate in high-stress environments, and CNC-milled carbon fiber parts deliver the structural integrity needed to ensure safety. Their high strength and stiffness make them ideal for critical components:

Airframe: CNC-milled carbon fiber fuselage frames withstand vertical lift loads of up to 15G (per FAA crashworthiness standards), compared to 10G for aluminum frames. For example, Archer Aviation’s Midnight eVTOL uses a CNC-milled carbon fiber central spar that supports the weight of four rotors and the battery pack, while remaining 40% lighter than steel.

Rotors and Propellers: Carbon fiber rotors (milled to precise aerodynamic profiles) resist bending and torsional stress during take-off. A study by the American Institute of Aeronautics and Astronautics (AIAA) found that CNC-milled carbon fiber rotors have a 70% lower failure rate than aluminum rotors under extreme wind conditions.

Fatigue resistance is equally critical. eVTOLs undergo repeated stress cycles—each flight involves take-off (high lift loads), forward flight (aerodynamic drag), and landing (impact forces)—which can cause metal components to weaken over time. Carbon fiber’s fatigue life is 2–3x longer than aluminum: after 10,000 flight cycles, a CNC-milled carbon fiber winglet retains 90% of its original strength, while an aluminum winglet retains only 65%. This reduces the risk of in-flight failures and extends the component’s service life from 5 years (aluminum) to 12 years (carbon fiber), aligning with eVTOLs’ expected 10–15 year operational lifespan.

CNC milling enhances these properties by minimizing material defects: traditional carbon fiber manufacturing (e.g., hand lay-up) often introduces air bubbles or fiber misalignment, weakening the part. CNC milling uses pre-cured composites with uniform fiber orientation, and its precision cutting avoids fraying—ensuring every part meets the same strength standards.

2.2 Manufacturing Efficiency and Quality Control (300 words)

eVTOL manufacturers face pressure to scale production while maintaining strict safety standards, and CNC-milled carbon fiber parts deliver on both fronts through precision and consistency.

CNC milling achieves tolerances of ±0.02 mm for critical components like rotor hubs—far tighter than the ±0.1 mm tolerance of aluminum machining. This precision eliminates the need for post-manufacturing adjustments (e.g., sanding or shimming), reducing assembly time by 25–30%. For example, Vertical Aerospace’s VA-X4 eVTOL uses 200+ CNC-milled carbon fiber parts, and the company reports that assembly time per aircraft dropped from 800 hours to 550 hours after switching from aluminum, as parts fit together seamlessly.

The repeatability of CNC milling ensures consistent quality across batches. Unlike manual composite manufacturing (where operator skill affects part quality), CNC machines follow pre-programmed tool paths, so every part is identical. This is critical for eVTOLs, where even small variations (e.g., a 0.1 mm difference in rotor thickness) can cause vibration or reduced performance. Industry tests show that CNC-milled carbon fiber parts have a defect rate of <0.5%, compared to 3–5% for manually made carbon fiber parts and 2% for aluminum parts.

CNC milling also streamlines quality control: integrated sensors in CNC machines monitor cutting force and tool wear in real time, flagging any deviations from specifications. This proactive quality check reduces the need for post-production inspection, further speeding up manufacturing.

2.3 Aerodynamic Optimization (300 words)

Aerodynamic efficiency directly impacts eVTOL range and energy use, and CNC-milled carbon fiber parts enable unprecedented optimization of aerodynamic performance.

First, CNC milling creates complex geometries that reduce drag and improve lift. For example:

Winglets: CNC-milled carbon fiber winglets with curved, tapered profiles reduce induced drag (drag caused by wingtip vortices) by 15–20%, compared to 10% for aluminum winglets. Lilium’s Jet eVTOL uses such winglets, boosting its range by 30 km.

Fuselage Fairings: CNC-milled fairings (streamlined covers for rotor arms and battery packs) have smooth, contoured shapes that eliminate air turbulence. A study by NASA found that these fairings reduce parasitic drag by 25%, cutting battery energy use by 18% during forward flight.

Second, CNC-milled carbon fiber parts achieve a smooth surface finish critical for aerodynamics. The high-speed milling process leaves a surface roughness (Ra) of <0.8 μm, compared to 1.6 μm for aluminum parts (after polishing). A smoother surface reduces skin friction drag—the resistance caused by air flowing over the part—by 10–12%. For eVTOLs, this translates to a 5–7% increase in range; for example, a 200 km-range eVTOL can extend to 214 km with CNC-milled carbon fiber parts.

CNC milling also enables integrated aerodynamic features that would be impossible with metal. For instance, some eVTOLs use CNC-milled carbon fiber leading edges with micro-grooves (0.2 mm deep) that redirect airflow, delaying stall (a sudden loss of lift) at low speeds—critical for safe vertical-to-horizontal flight transitions.

2.4 Cost-effectiveness in the Long Run (200 words)

While CNC-milled carbon fiber parts have higher upfront costs (20–30% more than aluminum), their long-term cost-effectiveness makes them a smart investment for eVTOLs.

Reduced maintenance is a key driver: carbon fiber’s corrosion resistance (no need for anti-rust treatments) and fatigue resistance mean fewer component replacements. A lifecycle analysis by Deloitte found that over 10 years, a CNC-milled carbon fiber airframe costs 45,000 to maintain, compared to 75,000 for an aluminum airframe—a 40% savings. Additionally, carbon fiber parts do not require periodic inspections for metal fatigue (e.g., crack checks), reducing maintenance labor costs by 25%.

Weight-related energy savings further lower costs: every 1 kg reduction in weight cuts annual battery charging costs by 120 (based on 1,000 flights/year and 0.15/kWh electricity). A 50 kg weight savings (typical for eVTOLs using carbon fiber) translates to 6,000 in annual savings. Over 10 years, this totals 60,000—more than offsetting the initial $15,000–20,000 premium for carbon fiber parts.

As eVTOL production scales (from hundreds to thousands of units annually), CNC milling costs are falling: bulk purchasing of carbon fiber blanks reduces material costs by 15%, and automated CNC lines cut labor costs by 20%. This trend will make CNC-milled carbon fiber parts even more cost-competitive in the future.

FAQs (300 words)

1. Are CNC-milled carbon fiber parts more expensive to manufacture than traditional materials?

Initially, yes—CNC-milled carbon fiber parts cost 20–30% more than aluminum parts due to higher carbon fiber material costs (20–30/kg vs. 2–3/kg for aluminum) and precision machining requirements. However, long-term savings offset this: reduced maintenance costs (40% lower over 10 years) and energy savings (50 kg weight reduction = $60,000 in 10 years) make them cost-effective. As production scales (e.g., 10,000+ eVTOLs/year), material and machining costs are expected to drop by 20–25%, narrowing the upfront gap.

2. How do CNC-milled carbon fiber parts handle high-temperature environments in eVTOL aircraft?

Carbon fiber itself withstands temperatures up to 400°C, but the polymer matrix (epoxy) typically softens at 120–180°C. To address this, CNC-milled parts use high-temperature resins (e.g., polyimide) with a glass transition temperature (Tg) of 250°C+ for components near electric motors (which reach 150–200°C). Additionally, CNC milling allows for precise application of heat-resistant coatings (e.g., ceramic films) to critical areas, ensuring parts maintain strength even in hot environments. Tests show these enhanced parts retain 95% of their stiffness at 200°C.

3. Can CNC-milled carbon fiber parts be repaired in case of damage?

Yes. Minor damage (e.g., small cracks or surface scratches) is repaired via patch bonding: a carbon fiber patch is bonded to the damaged area with epoxy, then milled to match the original shape (ensuring aerodynamic consistency). For more severe damage (e.g., broken rotor arms), CNC-milled parts’ modular design allows for easy replacement—most eVTOL manufacturers design components to be swapped out in <2 hours, minimizing downtime. A study by the European Union Aviation Safety Agency (EASA) found that repaired CNC-milled carbon fiber parts meet 90% of the original strength standards, making them safe for continued use.

LSI and NLP Keywords and Related Vocabulary

LSI Keywords

CNC-milled carbon fiber parts for eVTOL aircraft structures

Aerodynamic advantages of CNC-milled carbon fiber in eVTOL

Manufacturing efficiency of CNC-milled carbon fiber for eVTOL

Cost-effectiveness of CNC-milled carbon fiber in eVTOL aircraft

Structural performance of CNC-milled carbon fiber parts in eVTOL