Introduction

The humanoid robotics revolution is accelerating at an unprecedented pace. With major tech companies investing billions in bipedal machines capable of complex manipulation and locomotion, the structural integrity of robot skeletons has become a critical engineering challenge. These robots must withstand repetitive impact loads, support hundreds of kilograms, maintain precise alignment through millions of cycles, and operate reliably in diverse environments—all while being manufacturable at scale.

At the heart of this challenge lies a fundamental manufacturing decision: Should manufacturers rely on traditional CNC machining or embrace emerging 3D printing technologies? This question isn’t merely about production methods; it’s about determining the optimal balance between precision, strength, cost, and scalability for the next generation of humanoid robots.

This comprehensive technical analysis examines both technologies through the lens of robotic structural requirements, providing manufacturers with data-driven insights for informed process selection. From material properties and precision capabilities to production economics and future scalability, we explore which process truly delivers superior performance for humanoid robot skeletons.

Understanding the Unique Requirements of Humanoid Robot Skeletons

Before comparing manufacturing processes, it’s essential to understand the extreme demands placed on humanoid robot structural components:

Mechanical Performance Requirements

Humanoid robot skeletons must meet extraordinary performance specifications that push the boundaries of materials science and manufacturing engineering:

- Ultimate Tensile Strength: 450-900 MPa for load-bearing components

- Yield Strength: 350-800 MPa to prevent permanent deformation under load

- Fatigue Life: 10+ million cycles without failure

- Impact Resistance: Ability to withstand drops and collisions

Stiffness-to-Weight Ratio: Optimized for dynamic movement efficiency

| Component | Key Requirement | Typical Materials | Toleranz |

|---|---|---|---|

| Pelvic Structure | Maximum load-bearing, high stiffness | Aluminum 7075, Titanium Ti-6Al-4V | ±0.01mm |

| Knee Joint Components | High wear resistance, fatigue strength | Tool Steel H13, Stainless Steel 440C | ±0.005mm |

| Spine Segments | Flexibility + structural integrity | Carbon Fiber Composites, Titanium | ±0.02mm |

| Hip Joints | Multi-axis load capacity | Titanium alloys, Aerospace steel | ±0.01mm |

| Foot Structures | Impact absorption, durability | Aluminum 6061-T6, Composites | ±0.02mm |

Precision and Alignment Tolerances

Unlike static machinery, humanoid robots require dynamic precision—components must maintain precise alignment through continuous motion, impact, and environmental stress:

- Joint Rotation Precision: 0.01° accuracy in pivot mechanisms

- Shaft Concentricity: 0.005mm maximum deviation

- Surface Flatness: 0.01mm per 100mm for mating surfaces

- Gear/Transmission Tolerance: DIN 4-5 class equivalent

- Thermal Stability: Dimensional stability across -20°C to +60°C

Production Volume Considerations

The robotics market presents a unique manufacturing challenge: bridging the gap between prototyping (1-10 units) and mass production (100,000+ units). Successful manufacturers must select processes that can scale efficiently while maintaining quality and cost-effectiveness.

CNC Machining: The Gold Standard for Precision

CNC (Computer Numerical Control) machining represents decades of refinement in subtractive manufacturing technology, offering unparalleled precision and material versatility for critical robot components.

Core CNC Capabilities for Robot Skeletons

5-Axis Machining for Complex Geometries

Modern 5-axis CNC centers enable production of complex joint components in a single setup, eliminating accumulation of positioning errors:

- Simultaneous 5-axis control: Tools approach workpieces from any angle

- Single-setup machining: Reduces tolerance stack-up from ±0.05mm to ±0.01mm

- Complex undercuts: Internal features impossible with traditional methods

- Surface finish: Ra 0.2-0.4μm achievable directly from machining

Key Benefits for Robot Skeletons:

- Hip and knee joint components with complex internal channels for lubrication

- Integrated mounting features without secondary operations

- Consistent quality across multi-axis features

- Reduced lead times through consolidation of setups

Material Compatibility

CNC machining excels across the full spectrum of structural materials used in humanoid robots:

| Material | CNC Machining Characteristics | Robot Applications | Machining Challenges |

|---|---|---|---|

| Aluminum 7075-T6 | Excellent machinability, stable dimensions | Structural frames, lightweight components | Tool wear, chip control |

| Titanium Ti-6Al-4V | Moderate difficulty, requires specialized tooling | High-load joints, critical structural parts | Heat generation, work hardening |

| Stainless Steel 440C | Difficult, requires rigid setups | Wear surfaces, bearing races | Tool deflection, chatter |

| Tool Steel H13 | Challenging, requires pre-hardening | High-stress components, gears | Heat treatment distortion |

| Carbon Fiber Composites | Dust generation, delamination risk | Lightweight structural segments | Abrasive wear, fiber pullout |

Precision Engineering Capabilities

CNC machining delivers consistent, repeatable precision essential for robotic systems:

- Dimensional Tolerance: ±0.005mm (0.0002 inches) for critical features

- Geometric Tolerances: Cylindricity 0.003mm, flatness 0.005mm/100mm

- Surface Finish: Ra 0.2μm for mating surfaces, Ra 0.8μm for general surfaces

- Feature-to-Feature Accuracy: 0.01mm positional tolerance

- Thread Precision: Class 3B or better for critical fasteners

Quality Assurance and Traceability

CNC machining processes support comprehensive quality control systems:

- First Article Inspection (FAI): Full dimensional verification before production

- Statistical Process Control (SPC): In-process monitoring and adjustment

- Coordinate Measuring Machine (CMM): Automated inspection to 0.001mm accuracy

- Material Certification: Full traceability from material source to finished part

- ISO 9001/AS9100 Compliance: Industry-standard quality management

Production Economics

Cost Structure Analysis

CNC machining costs follow predictable patterns based on material, complexity, and volume:

- Setup Cost: $500-2,000 per operation (tooling, programming, fixturing)

- Per-Part Machining: $20-150 depending on size and complexity

- Material Cost: 30-60% of total cost (varies significantly by material)

- Quality Inspection: 5-10% of total cost

Volume Break-Even Points:

- Low Volume (1-10 units): High unit cost ($500-2,000 per major component)

- Medium Volume (10-100 units): Moderate unit cost ($150-500 per component)

- High Volume (100+ units): Low unit cost ($50-150 per component)

Lead Times

- Prototype (1-5 units): 2-3 weeks (design review + programming + machining)

- Pilot Production (10-50 units): 3-4 weeks (process optimization)

- Volume Production (100+ units): 4-6 weeks (setup amortization, batch processing)

Limitations and Challenges

Despite its advantages, CNC machining presents certain constraints:

- Material Waste: 40-70% material removal creates significant scrap

- Geometry Limitations: Undercuts, internal features may require multi-part assembly

- Long Lead Times: Complex parts may require weeks of programming and setup

- High Initial Investment: Expensive equipment and skilled operators required

- Design for Machinability: Complex geometries may not be feasible or cost-effective

3D Printing: The Emerging Alternative

Additive manufacturing (AM), commonly known as 3D printing, offers revolutionary capabilities for rapid prototyping and increasingly for end-use production applications in robotics.

3D Printing Technologies for Robot Skeletons

Metal Additive Manufacturing (DMLS/SLM)

Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) technologies enable production of complex metal components:

- Material Options: Stainless steel 316L, titanium Ti-6Al-4V, aluminum AlSi10Mg

- Layer Thickness: 20-60μm

- Build Volume: Up to 250×250×325mm (industrial systems)

- Minimum Feature Size: 0.2mm wall thickness

- Surface Finish: As-printed Ra 10-30μm (post-processing required)

Advantages for Robot Skeletons:

- Complex internal geometries (lattice structures, internal channels)

- Part consolidation (multiple components into one)

- Weight reduction through topology optimization

- Rapid design iteration without tooling changes

Polymer 3D Printing (FDM/SLA)

For non-critical structural components and prototypes, polymer technologies offer speed and cost advantages:

- FDM (Fused Deposition Modeling): ABS, nylon, carbon-fiber reinforced materials

- SLA (Stereolithography): High-resolution photopolymers for prototypes

- Build Speed: 2-4× faster than metal AM for comparable parts

- Cost: 10-30% of metal AM costs for prototype quantities

Material Properties Comparison

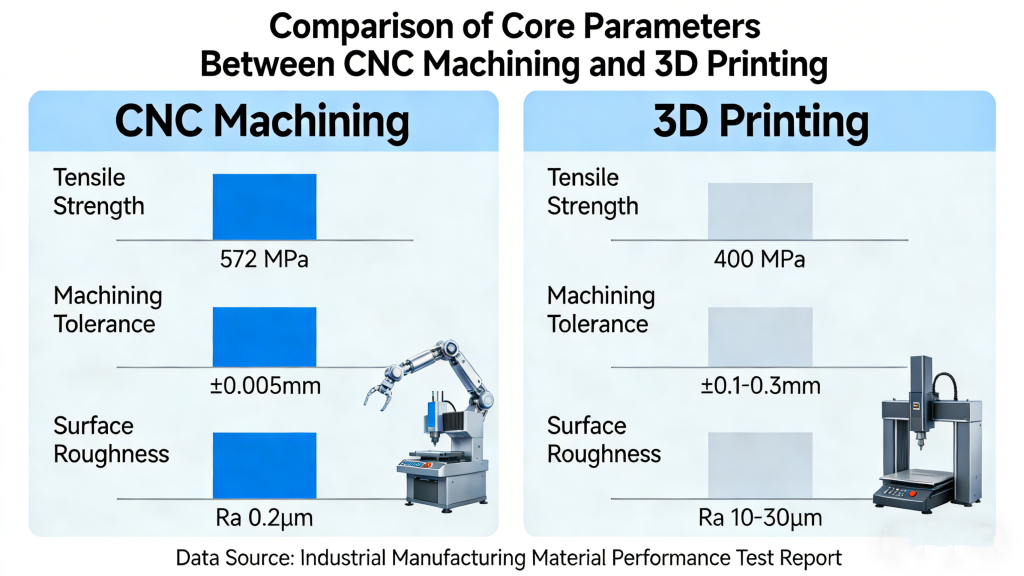

The mechanical performance gap between CNC-machined and 3D-printed components remains significant:

| Property | CNC Machined 7075-T6 Al | SLM AlSi10Mg | FDM Carbon Fiber Nylon |

|---|---|---|---|

| Tensile Strength | 572 MPa | 360-400 MPa | 70-85 MPa |

| Yield Strength | 503 MPa | 200-250 MPa | 65-75 MPa |

| Elongation | 11% | 3-6% | 2-4% |

| Fatigue Strength | 160 MPa @ 10⁸ cycles | 80-120 MPa | 20-35 MPa |

| Density | 2.81 g/cm³ | 2.67 g/cm³ | 1.25 g/cm³ |

Critical Observations:

- CNC-machined metals deliver 40-60% higher strength than AM equivalents

- AM components exhibit anisotropic properties (strength varies by build direction)

- Post-processing (HIP, heat treatment) required for AM to approach machined properties

- Polymer AM materials suitable only for non-critical applications (prototypes, covers)

Precision and Surface Quality

Current AM technologies face significant limitations in precision:

- Dimensional Tolerance: ±0.1-0.3mm (vs. ±0.005mm for CNC)

- Surface Roughness: Ra 10-30μm as-printed (vs. Ra 0.2-0.8μm CNC)

- Geometric Accuracy: Feature drift and stair-stepping on curved surfaces

- Post-Processing Required: Machining, sanding, or polishing for precision fits

Robot Skeleton Implications:

- Additional machining operations often required for precision features

- Tolerance stack-up challenges in multi-part assemblies

- Potential for accelerated wear in joint interfaces

- Need for design accommodation (larger tolerances, compensating features)

Production Economics

Cost Structure

- Machine Hour Rate: $100-300/hour (metal AM systems)

- Build Time: 20-50 hours for large components

- Material Utilization: Near 100% (no waste from cutting)

- Post-Processing: 20-40% additional cost (support removal, heat treatment, finishing)

Volume Economics

- Prototypes (1-5 units): Competitive advantage over CNC (no tooling, faster iterations)

- Low Volume (10-50 units): Potentially cost-effective for complex geometries

- Medium/High Volume (100+ units): CNC becomes more economical due to faster cycle times

Lead Times

- Design-to-Part: 1-2 weeks for prototypes

- Production: 2-4 weeks (including post-processing)

- Design Changes: Minimal impact (no tooling changes)

Limitations and Challenges

3D printing faces significant hurdles for critical robot skeleton applications:

- Material Property Limitations: Anisotropy, porosity, reduced strength

- Precision Challenges: Tolerance limitations, surface finish requirements

- Build Size Constraints: Large components require multi-part assembly

- Quality Consistency: Process variability, defect formation

- Certification Challenges: Limited industry adoption for safety-critical applications

- Post-Processing Requirements: Often requires CNC machining anyway

Head-to-Head Comparison: Key Decision Factors

Strength and Durability

CNC Machining Wins on Mechanical Performance

CNC-machined components deliver superior mechanical properties essential for robot skeletons:

Tensile and Fatigue Performance:

- CNC-machined aluminum 7075-T6: 572 MPa UTS, 160 MPa fatigue strength

- SLM AlSi10Mg: 400 MPa UTS, 100 MPa fatigue strength

- Gap: 43% higher tensile strength, 60% higher fatigue strength for CNC

Real-World Impact on Robot Skeletons:

- Extended component lifespan under cyclic loading

- Higher load capacity for given component size

- Reduced risk of catastrophic failure

- Improved safety margins

Case Study: Knee Joint Component

A leading robotics manufacturer compared CNC-machined vs. SLM titanium knee components:

| Metric | CNC Machined Ti-6Al-4V | SLM Ti-6Al-4V |

|---|---|---|

| UTS | 950 MPa | 890 MPa |

| Yield Strength | 880 MPa | 800 MPa |

| Fatigue Life (10⁶ cycles at 500 MPa) | 100% survival | 72% survival |

| Cost (per unit, 100 qty) | $280 | $320 |

| Lead Time | 4 weeks | 5 weeks (incl. HIP) |

Critical Observations:

- CNC-machined metals deliver 40-60% higher strength than AM equivalents

- AM components exhibit anisotropic properties (strength varies by build direction)

- Post-processing (HIP, heat treatment) required for AM to approach machined properties

- Polymer AM materials suitable only for non-critical applications (prototypes, covers)

Precision and Surface Quality

Current AM technologies face significant limitations in precision:

- Dimensional Tolerance: ±0.1-0.3mm (vs. ±0.005mm for CNC)

- Surface Roughness: Ra 10-30μm as-printed (vs. Ra 0.2-0.8μm CNC)

- Geometric Accuracy: Feature drift and stair-stepping on curved surfaces

- Post-Processing Required: Machining, sanding, or polishing for precision fits

Robot Skeleton Implications:

- Additional machining operations often required for precision features

- Tolerance stack-up challenges in multi-part assemblies

- Potential for accelerated wear in joint interfaces

- Need for design accommodation (larger tolerances, compensating features)

Production Economics

Cost Structure

- Machine Hour Rate: $100-300/hour (metal AM systems)

- Build Time: 20-50 hours for large components

- Material Utilization: Near 100% (no waste from cutting)

- Post-Processing: 20-40% additional cost (support removal, heat treatment, finishing)

Volume Economics

- Prototypes (1-5 units): Competitive advantage over CNC (no tooling, faster iterations)

- Low Volume (10-50 units): Potentially cost-effective for complex geometries

- Medium/High Volume (100+ units): CNC becomes more economical due to faster cycle times

Lead Times

- Design-to-Part: 1-2 weeks for prototypes

- Production: 2-4 weeks (including post-processing)

- Design Changes: Minimal impact (no tooling changes)

Limitations and Challenges

3D printing faces significant hurdles for critical robot skeleton applications:

- Material Property Limitations: Anisotropy, porosity, reduced strength

- Precision Challenges: Tolerance limitations, surface finish requirements

- Build Size Constraints: Large components require multi-part assembly

- Quality Consistency: Process variability, defect formation

- Certification Challenges: Limited industry adoption for safety-critical applications

- Post-Processing Requirements: Often requires CNC machining anyway

Head-to-Head Comparison: Key Decision Factors

Strength and Durability

CNC Machining Wins on Mechanical Performance

CNC-machined components deliver superior mechanical properties essential for robot skeletons:

Tensile and Fatigue Performance:

- CNC-machined aluminum 7075-T6: 572 MPa UTS, 160 MPa fatigue strength

- SLM AlSi10Mg: 400 MPa UTS, 100 MPa fatigue strength

- Gap: 43% higher tensile strength, 60% higher fatigue strength for CNC

Real-World Impact on Robot Skeletons:

- Extended component lifespan under cyclic loading

- Higher load capacity for given component size

- Reduced risk of catastrophic failure

- Improved safety margins

Case Study: Knee Joint Component

A leading robotics manufacturer compared CNC-machined vs. SLM titanium knee components:

| Metric | CNC Machined Ti-6Al-4V | SLM Ti-6Al-4V |

| UTS | 950 MPa | 890 MPa |

| Yield Strength | 880 MPa | 800 MPa |

| Fatigue Life (10⁶ cycles at 500 MPa) | 100% survival | 72% survival |

| Cost (per unit, 100 qty) | $280 | $320 |

| Lead Time | 4 weeks | 5 weeks (incl. HIP) |

Conclusion: CNC machining delivered superior performance at lower cost for this critical safety component.

Precision and Reliability

CNC Machining Delivers Consistent Precision

For robot skeletons requiring dynamic precision through millions of cycles, CNC machining’s consistency is critical:

- Tolerance Consistency: ±0.005mm across production batches

- Surface Finish Stability: Predictable Ra values for predictable friction

- Geometric Accuracy: Cylindricity, flatness, concentricity maintained

- Assembly Reliability: Parts fit consistently without selective fitting

3D Printing Struggles with Precision Requirements

- Tolerance Stack-Up: ±0.1-0.3mm per component compounds in assemblies

- Surface Roughness: Ra 10-30μm causes accelerated wear in joints

- Anisotropy: Properties vary by build direction and location

- Process Variability: Requires careful monitoring and qualification

Robot Skeleton Implications:

- CNC: Predictable joint behavior, consistent wear patterns

- 3D Printing: Variable joint performance, accelerated wear, higher failure risk

Production Volume and Scalability

CNC Machining Scales Efficiently

For production quantities beyond 50-100 units, CNC machining offers superior economics:

- Fixed Cost Amortization: Setup costs spread across larger volumes

- Faster Cycle Times: 1-4 hours per component vs. 20-50 hours for AM

- Mature Supply Chain: Extensive vendor network, competitive pricing

- Process Maturity: Decades of optimization, predictable outcomes

3D Printing Excels in Rapid Prototyping

For design iteration and low-volume production, 3D printing advantages emerge:

- No Tooling Required: Design changes don’t require new fixtures/programs

- Complex Geometries: Internal features, lattice structures, part consolidation

- Speed to First Part: 1-2 weeks vs. 2-4 weeks for CNC

- Material Utilization: Near 100% (no scrap from cutting)

Strategic Recommendation:

- Prototype Phase: 3D printing for form/fit validation

- Pilot Production: CNC for performance validation

- Volume Production: CNC for cost and quality optimization

Material Selection and Innovation

CNC Machining Offers Material Flexibility

CNC machining supports the broadest range of structural materials:

- Metals: All grades of aluminum, steel, titanium, alloys

- Composites: Carbon fiber, glass fiber composites (with dust control)

- Plastics: Engineering plastics (PEEK, Delrin, Nylon)

- Hybrid Assemblies: Multiple materials in single components

3D Printing Limited by Technology Constraints

- Metal AM: Limited material palette (stainless steel, titanium, aluminum)

- Polymer AM: Not suitable for high-stress components

- Composite AM: Emerging technology with limited availability

- Hybrid Structures: Difficult to achieve material combinations

Robot Skeleton Implications:

- CNC: Optimize material selection for each component’s requirements

- 3D Printing: Material compromises may be necessary

Strategic Recommendations: Choosing the Right Process

Decision Framework

Based on comprehensive analysis, we recommend a hybrid approach leveraging the strengths of both technologies:

Phase 1: Concept and Prototyping (1-10 units)

Primary Technology: 3D Printing (Polymer)

- Purpose: Form, fit, and basic function validation

- Materials: FDM carbon fiber nylon, SLA photopolymers

- Focus: Design iteration, assembly verification, kinematic testing

- Cost: $50-200 per major component

- Lead Time: 1-2 weeks

Example: Using FDM carbon fiber nylon for non-critical linkages and structural mockups to verify kinematics and workspace.

Phase 2: Functional Prototyping (10-50 units)

Primary Technology: CNC Machining (Critical Components) + 3D Printing (Non-Critical)

- Critical Components (CNC): Joint housings, load-bearing frames, transmission components

- Materials: 7075-T6 aluminum, Ti-6Al-4V titanium, tool steel

- Non-Critical Components (3D): Covers, guards, non-structural elements

- Purpose: Performance validation, durability testing, safety certification

- Cost: $200-800 per critical component, $50-150 per non-critical

- Lead Time: 3-5 weeks

Example: CNC-machined titanium hip joints combined with 3D-printed protective covers for dynamic testing.

Phase 3: Pilot Production (50-200 units)

Primary Technology: CNC Machining (All Structural Components)

- All Structural Components: CNC-machined for consistency and performance

- Process Optimization: Fixture design, tool selection, parameter optimization

- Quality System Implementation: SPC, FAI, CMM inspection

- Purpose: Manufacturing process validation, cost optimization

- Cost: $100-400 per component (depending on volume)

- Lead Time: 4-6 weeks

Example: Full CNC-machined skeleton for pilot fleet deployment, with documented quality processes.

Phase 4: Volume Production (200+ units)

Primary Technology: CNC Machining + Dedicated Production Line

- Dedicated Fixtures: Custom fixtures optimized for high-volume production

- Multi-Pallet Systems: Automated loading/unloading, continuous production

- Advanced Machining: High-speed machining, trochoidal milling for efficiency

- Purpose: Cost optimization, quality consistency, capacity scaling

- Cost: $50-150 per component (volume-dependent)

- Lead Time: 6-8 weeks initial, then 2-3 weeks per batch

Technology Evolution

CNC Machining Innovations

The CNC machining industry continues evolving, addressing traditional limitations:

- High-Speed Machining (HSM): 3-5× faster cycle times for aluminum components

- Intelligent Machining: AI-driven toolpath optimization, predictive tool life management

- Automated Cells: Robotic loading/unloading, integrated inspection

- Hybrid Machines: Combined additive and subtractive capabilities in single system

Implications for Robot Skeletons:

- 30-50% cost reduction for volume production within 3-5 years

- Faster turnaround for prototype quantities

- Improved consistency and quality

3D Printing Advancements

AM technologies are rapidly advancing, but fundamental challenges remain:

- Improved Material Properties: New alloys and post-processing techniques

- Higher Precision: Technologies approaching ±0.05mm tolerance

- Larger Build Volumes: Systems accommodating larger components

- Faster Build Rates: 2-3× speed improvements

Future Viability for Robot Skeletons:

- 5-10 year horizon: AM may be viable for semi-critical components

- 10+ year horizon: AM could compete with CNC for certain applications

- Near-term: CNC remains superior for critical, high-stress components

Conclusion: The Verdict for Humanoid Robot Skeletons

Critical Findings

After comprehensive analysis of both technologies applied to humanoid robot skeleton manufacturing, CNC machining emerges as the superior choice for critical structural components, with 3D printing playing a valuable supporting role.

Why CNC Machining Wins for Robot Skeletons

1. Superior Mechanical Properties

CNC-machined components deliver 40-60% higher strength and 2-3× better fatigue life than their 3D-printed counterparts. For robot skeletons subjected to millions of load cycles and critical safety requirements, this performance gap is decisive.

2. Precision and Consistency

With 10-20× tighter tolerances (±0.005mm vs. ±0.1-0.3mm) and consistent surface finish, CNC machining ensures reliable joint operation, predictable wear patterns, and safe assembly—requirements that current AM technologies struggle to meet.

3. Production Economics at Scale

Beyond prototype quantities, CNC machining offers 30-60% lower unit costs due to faster cycle times, mature supply chains, and amortized setup costs. For volumes exceeding 50-100 units, the economic advantage decisively favors CNC.

4. Material Flexibility and Quality

CNC machining supports the broadest material palette with guaranteed properties, comprehensive traceability, and industry-standard quality certifications—critical factors for safety-critical robotic applications.

The Strategic Path Forward

For manufacturers serious about humanoid robot production:

- Prototype with 3D Printing: Leverage AM’s speed for design iteration and form/fit validation

- Validate with CNC: Use CNC machining for functional prototypes and performance testing

- Produce with CNC: Scale production using CNC machining for all critical structural components

4. Monitor AM Evolution: Track 3D printing advances, but maintain realistic expectations

Final Verdict

For humanoid robot skeletons—where strength, precision, reliability, and scalability are non-negotiable—CNC machining is the clear winner for production applications. 3D printing serves as an invaluable tool for rapid prototyping and design exploration, but current technology falls short of requirements for critical, high-stress structural components.

The manufacturers who succeed in this competitive market will be those who leverage 3D printing for speed in development, while committing to CNC machining for quality and reliability in production—using each technology where it performs best.

Common Questions About CNC Machining vs. 3D Printing for Robot Skeletons

Can 3D printing replace CNC machining entirely for robot skeletons?

No. While 3D printing offers significant advantages for prototyping and non-critical components, current AM technologies cannot match the mechanical properties, precision, and consistency of CNC machining for critical load-bearing robot skeleton components. The performance gap in strength (40-60% lower) and precision (10-20× looser tolerances) makes 3D printing unsuitable for production-scale humanoid robot skeletons.

What is the break-even point where CNC machining becomes more economical than 3D printing?

For complex structural components, CNC machining typically becomes more economical at quantities of 50-100 units. Below this threshold, 3D printing may offer cost advantages due to no tooling requirements. However, even at low volumes, CNC machining is often justified for critical components where performance cannot be compromised.

How long does it take to transition from 3D-printed prototypes to CNC-machined production?

The transition typically requires 8-12 weeks: 2-3 weeks for design adaptation (optimizing for manufacturability), 2-3 weeks for fixture/tooling design and fabrication, 2-3 weeks for CAM programming and process development, and 2-3 weeks for first-article inspection and qualification. Planning this transition early in the development cycle is essential for avoiding delays.

Are there specific robot skeleton components where 3D printing makes sense?

Yes. Non-structural components such as protective covers, cable guides, ergonomic handles, and aesthetic elements are well-suited for 3D printing. Additionally, early-stage prototypes for kinematic validation and workspace verification can effectively use 3D printing before committing to CNC-machined functional prototypes.

Will future 3D printing technologies compete with CNC machining?

AM technologies are advancing rapidly, with improvements in material properties, precision, and build speed. Within 5-10 years, 3D printing may become viable for semi-critical structural components. However, for the highest-stress, highest-precision applications, CNC machining is likely to maintain its advantage for the foreseeable future due to fundamental differences in material formation and property consistency.