Whether you’re developing surgical robots, industrial automation systems, or advanced prosthetics, managing titanium part costs is critical to staying competitive. This comprehensive guide reveals proven strategies that can reduce your small-batch titanium robot parts manufacturing costs by up to 40% without compromising quality, precision, or performance.

Cost and practicality

Understanding the Titanium Cost Challenge

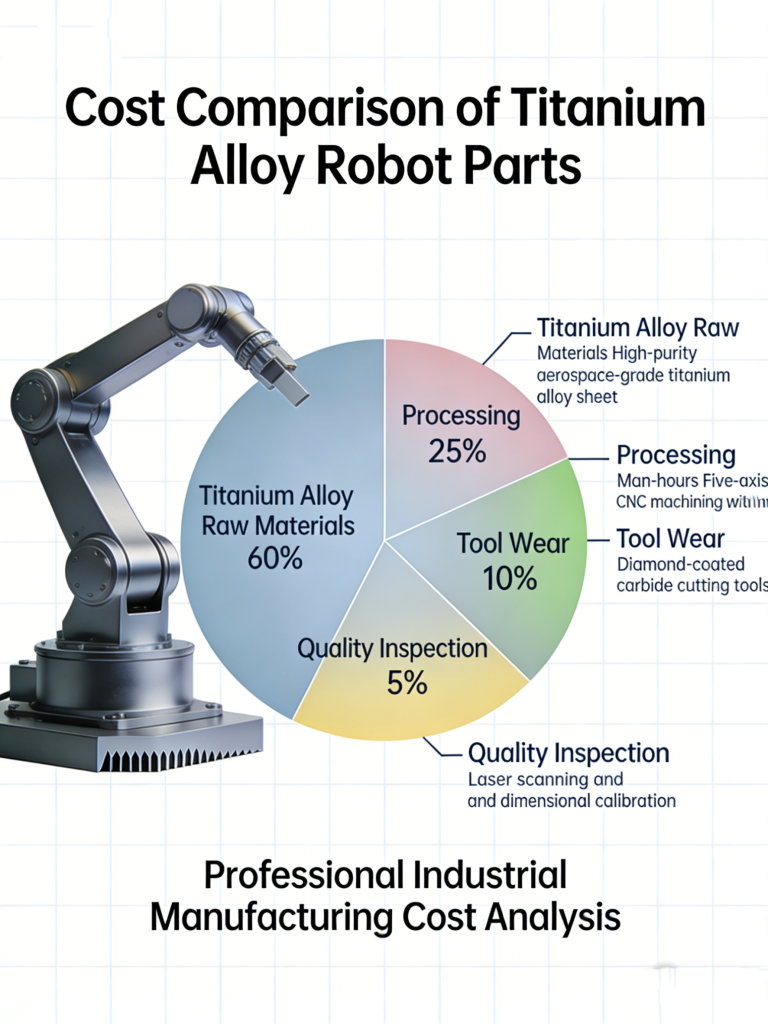

Why Titanium is Expensive to Machine

Titanium alloys, particularly Ti-6Al-4V (Grade 5), present unique machining challenges that directly impact costs:

Material Properties Driving Costs:

- Low thermal conductivity: Heat concentrates in the cutting zone, accelerating tool wear

- High chemical reactivity: Titanium welds to cutting tools, causing premature failure

- Work hardening: Material hardens during cutting, requiring more aggressive machining

- Low modulus of elasticity: Part deflection during machining affects dimensional accuracy

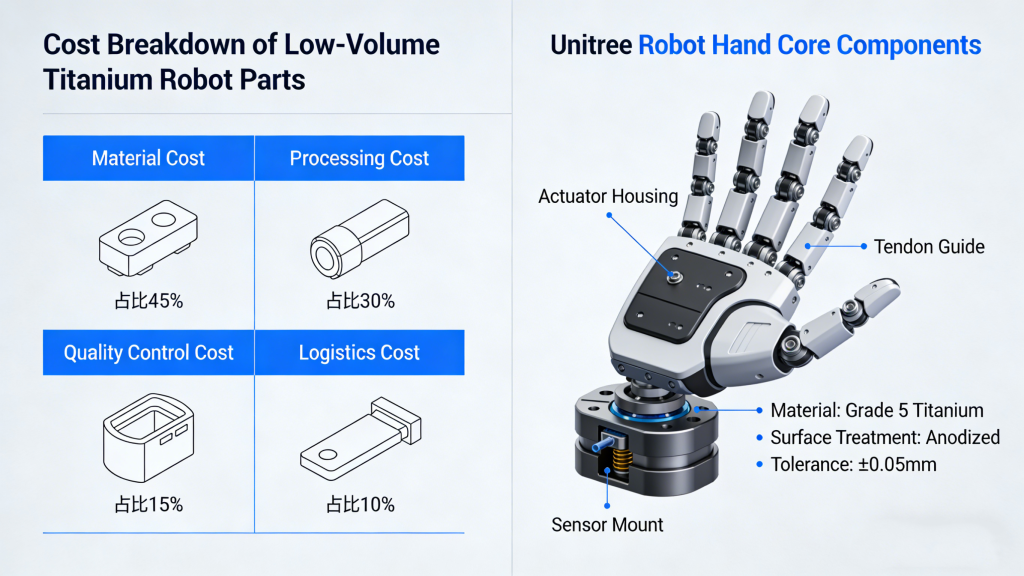

Small-Batch Production Inefficiencies

Unlike high-volume production, small-batch titanium machining faces additional cost hurdles:

- High setup costs: Multiple machine setups for complex geometries

- Optimized tool paths not justified: Custom programming costs outweigh savings

- Material waste: Inefficient nesting for limited quantities

- Quality overhead: Full inspection protocols applied to small quantities

Industry data shows that small-batch titanium parts can cost 3-5 times more than equivalent aluminum or steel components, creating significant barriers to innovation.

Design for Manufacturing (DFM): The Foundation of Cost Reduction

Simplify Geometry Without Sacrificing Function

The most significant cost reduction opportunity lies in intelligent part design:

Key DFM Principles for Titanium:

- Minimize deep pockets: Reduce tool extension and deflection

- Consolidate features: Combine multiple parts into single components where possible

- Standardize features: Use consistent radii, thread sizes, and tolerances

- Optimize wall thickness: Balance strength requirements with machinability

- Eliminate unnecessary precision: Tighten tolerances only where functionally required

Real-world impact: One medical robotics company reduced titanium component costs by 35% simply by loosening non-critical tolerances from ±0.001mm to ±0.005mm on non-interface surfaces.

Material Selection Optimization

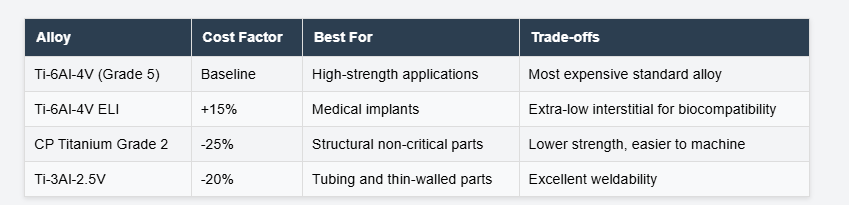

While titanium offers exceptional properties, not all titanium alloys are created equal:

Cost-Effective Titanium Options:

Strategy: Use Grade 5 titanium only for critical load-bearing components. Substitute with CP Grade 2 for covers, housings, and non-structural parts where possible.

Advanced Machining Strategies

High-Speed Machining (HSM) Applications

Contrary to intuition, increasing cutting speeds can actually reduce costs for titanium:

HSM Benefits:

- Reduced cutting forces: Less tool deflection and better accuracy

- Shorter cycle times: Faster material removal despite higher speeds

- Improved surface finish: Reduces or eliminates post-processing

- Extended tool life: Properly applied HSM can actually decrease tool wear

Optimal HSM Parameters for Ti-6Al-4V:

- Cutting speed: 60-100 m/min (vs. 30-50 m/min conventional)

- Feed rate: 0.08-0.15 mm/tooth

- Depth of cut: 0.5-2.0 mm (light, shallow cuts)

- Radial engagement: 5-15% of tool diameter

Implementation note: HSM requires rigid machines, premium tooling, and experienced programmers. The investment typically pays off for parts exceeding $1,000 in value.

Adaptive Machining and Tool Monitoring

Real-time machining optimization offers significant cost savings for complex titanium parts:

Adaptive Control Technologies:

- Acoustic emission monitoring: Detect tool wear before failure

- Force-based optimization: Adjust feed rates in real-time

- Vibration damping: Reduce chatter and improve surface finish

- Predictive maintenance: Schedule tool changes proactively

Results: Manufacturers implementing adaptive control report 20-30% reduction in tooling costs and 15% improvement in cycle times for titanium applications.

Process Optimization and Technology Leverage

5-Axis Machining for Reduced Setups

Multi-axis capabilities dramatically reduce titanium part costs through setup consolidation:

5-Axis Advantages for Titanium:

- Single-setup machining: Eliminates positional errors between setups

- Reduced cycle time: No need for multiple part repositioning

- Better tool access: Use shorter, more rigid tooling

- Improved quality: Consistent datum reference throughout machining

Cost impact: Complex titanium brackets requiring 3+ 3-axis setups can often be completed in a single 5-axis operation, reducing machining time by 40-60% and eliminating accumulated setup errors.

Additive Manufacturing Integration

Hybrid additive-subtractive approaches offer compelling cost advantages:

Strategic AM Applications:

- Near-net shape blanks: Reduce material waste from 80% to 20%

- Internal features: Create complex internal channels impossible to machine

- Part consolidation: Combine multiple components into single AM parts

- Rapid prototyping: Fast design iterations before committing to machining

Cost example: A titanium robotic wrist component costing $2,500 when fully machined from solid can be produced for $1,200 using a hybrid approach: AM near-net shape ($300) + finish machining ($900).

Smart Procurement and Supplier Management

Optimize Order Quantities and Consolidation

Small-batch titanium machining costs are highly sensitive to order size and frequency:

Volume Optimization Strategies:

- Order batching: Combine multiple small projects into single runs

- Blanket orders: Commit to annual quantities for better pricing

- Family part production: Group similar parts for efficient setups

- Inventory management: Maintain strategic stock of common components

Quantum cost jumps: Order quantities of 1-5 parts often cost 2-3× more per unit than orders of 10-50 parts. Finding sweet spots in ordering can yield immediate savings.

Supplier Selection and Partnership

The right titanium machining partner makes a substantial difference in total costs:

Key Supplier Capabilities:

- Titanium specialization: Dedicated titanium expertise and tooling

- Advanced equipment: 5-axis capabilities and high-speed machining

- Quality certifications: ISO 9001, AS9100 for aerospace/robotics

- Engineering support: DFM consultation and design optimization

- Flexibility: Ability to handle prototype-to-production transitions

Long-term partnership benefits: Suppliers who understand your product line can optimize processes across projects, leading to cumulative cost reductions of 20-30% over time.

Quality Assurance Balance

Targeted Inspection Strategies

Full inspection of every titanium feature is often unnecessary and expensive:

Risk-Based Inspection:

- Critical characteristics only: Tight inspection on functional surfaces

- Statistical process control: Monitor process rather than every part

- First-article inspection (FAI): Validate initial run, then reduce frequency

- Automated inspection: CMM programs for repetitive measurements

Cost impact: Reducing inspection scope by 40% on non-critical features can cut quality assurance costs by 25-35% without compromising part integrity.

Preventive Quality Measures

Invest in prevention rather than detection:

Quality Prevention Strategies:

- Robust fixturing: Eliminates part movement during machining

- Temperature control: Maintains consistent machining environment

- Tool management systems: Ensures sharp, properly indexed tools

- In-process gauging: Real-time monitoring of critical dimensions

ROI: Every dollar invested in prevention typically saves $3-10 in rework, scrap, and inspection costs.

Technology and Innovation Adoption

Digital Twin and Simulation

Advanced simulation tools can prevent costly mistakes before machining begins:

Simulation Capabilities:

- Tool path verification: Detect collisions and inefficient moves

- Force prediction: Optimize cutting parameters for titanium

- Thermal modeling: Predict heat-affected zones

- Cycle time optimization: Reduce machining time through virtual trials

Case study: A robotics company using simulation reduced titanium part cycle times by 18% and eliminated 3 costly tool collisions per year, saving over $50,000 annually.

Automation for Repetitive Tasks

Automation makes sense even for small-batch titanium production:

Automation Opportunities:

- Automated tool changers: Reduce setup times between parts

- Robotic part loading: Consistent positioning and reduced labor

- In-process probing: Automated feature measurement

- Lights-out machining: Unattended operation for long-running titanium jobs

Implementation strategy: Start with high-value, long-cycle parts. Even one automated titanium part can justify automation investment through consistent quality and reduced labor.

Real-World Success Stories

Case 1: Surgical Robot Manufacturer

Challenge: Complex titanium surgical instruments costing $800-1,200 each in quantities of 5-10.

Solution Implementation:

- DFM review reduced feature count by 15%

- Switched from Grade 5 to CP Grade 2 for non-critical handles

- Implemented 5-axis single-setup machining

- Optimized order batching from monthly to quarterly

Results:

- Cost reduction: 42% (from $1,000 to $580 average)

- Lead time: Reduced from 8 weeks to 3 weeks

- Quality: Maintained with tighter process control

- Annual savings: $210,000

Case 2: Industrial Automation Systems

Challenge: Titanium gripper components costing $650 each for small-batch runs.

Solution Implementation:

- Adopted high-speed machining parameters

- Implemented adaptive control systems

- Redesigned for near-net additive manufacturing blanks

- Established strategic supplier partnership

Results:

- Cost reduction: 38% (from $650 to $403)

- Tool life: Improved by 30%

- Cycle time: Reduced by 22%

- Annual production: Increased by 3x with same budget

Implementation Roadmap

Phase 1: Quick Wins (0-3 months)

Immediate cost reduction opportunities:

- Review all titanium parts for DFM optimization potential

- Identify non-Grade 5 titanium substitution opportunities

- Optimize order quantities and batching

*. Audit current inspection requirements

Expected savings: 15-20% cost reduction

Phase 2: Process Optimization (3-9 months)

Strategic improvements:

- Implement 5-axis machining for complex parts

- Adopt high-speed machining parameters

- Deploy adaptive control and monitoring

*. Establish preferred supplier relationships

Expected savings: Additional 10-15% reduction (cumulative 25-35%)

Phase 3: Advanced Integration (9-18 months)

Long-term strategic initiatives:

- Integrate additive manufacturing where advantageous

- Deploy digital twin simulation capabilities

- Implement targeted automation

*. Develop comprehensive titanium expertise in-house

Expected savings: Additional 5-10% reduction (cumulative 30-45%)

Common Pitfalls to Avoid

Mistake 1: Over-Specifying Material Grade

Using Ti-6Al-4V Grade 5 when CP Grade 2 would suffice is one of the most common titanium cost traps.

Solution: Conduct material property analysis and use the lowest grade that meets functional requirements.

Mistake 2: Excessive Precision

Titanium parts are often over-toleranced, especially on non-critical surfaces.

Solution: Apply tolerance optimization: ±0.005mm on functional surfaces only, ±0.025mm elsewhere where possible.

Mistake 3: Ignoring Tooling Economics

Using cheap tooling for titanium machining is false economy.

Solution: Invest in premium tooling specifically designed for titanium. The 30-50% higher tooling cost is recovered 3-5× through extended life and better performance.

Mistake 4: Failing to Consolidate Orders

Multiple small orders of titanium parts incur repeated setup costs.

Solution: Plan ahead and consolidate orders into larger batches wherever possible.

Conclusion

Reducing small-batch titanium robot parts costs is not about compromising quality—it’s about strategic optimization across the entire production lifecycle. By implementing the strategies outlined in this guide, manufacturers can achieve 30-40% cost reductions while maintaining or improving precision, quality, and performance.

The journey to cost-effective titanium manufacturing begins with intelligent design and extends through advanced machining technologies, smart procurement, and continuous process improvement. Start with the quick wins, build momentum with process optimization, and leverage advanced technologies for maximum long-term savings.

Titanium’s exceptional properties make it ideal for high-performance robotics. With the right approach, these parts need not come with prohibitive price tags. By combining engineering expertise, manufacturing innovation, and strategic thinking, manufacturers can unlock titanium’s full potential while keeping costs under control.

Frequently Asked Questions

What’s the realistic cost reduction achievable for titanium robot parts?

Manufacturers implementing comprehensive strategies typically achieve 30-40% cost reductions. Quick wins alone can deliver 15-20%, while full optimization across design, process, and procurement can reach 40% or more.

Can I really switch from Ti-6Al-4V to cheaper titanium grades?

Yes, but only after careful analysis. CP Grade 2 is 25-30% cheaper and suitable for many structural applications. However, critical load-bearing components may still require Grade 5’s superior strength-to-weight ratio.

Is 5-axis machining worth the investment for small titanium batches?

For complex parts requiring multiple 3-axis setups, 5-axis machining typically pays off with 40-60% faster cycle times and better quality. The break-even point is usually around 10-15 complex titanium parts per year.

How does additive manufacturing integrate with titanium machining?

Hybrid approaches work best: use additive manufacturing for near-net shapes (reducing material waste from 80% to 20%), then precision machine critical features. This approach can cut costs by 30-50% for suitable geometries.

What’s the minimum order quantity to get reasonable titanium pricing?

While costs drop significantly between 1-5 and 10-50 parts, there’s no universal minimum. Order consolidation, family part production, and blanket orders can all help achieve volume pricing even for small individual quantities.