Part 1: Understanding the Cost Components in CNC Machining (800 words)

1.1 Equipment-related Costs (300 words)

Equipment costs account for 20–30% of total CNC part costs, with purchase and depreciation being the largest share. CNC machine prices vary drastically by capability: entry-level 3-axis mills cost 20,000–50,000, mid-range 5-axis machines 100,000–300,000, and high-precision (±0.001mm) models over 500,000. Depreciation spreads this cost over the machine’s lifespan (typically 7–10 years, 10,000–20,000 operating hours). For example, a 100,000 3-axis mill producing 100,000 parts over 10 years allocates 1 per part to depreciation; if production scales to 1,000,000 parts (via longer shifts or higher efficiency), depreciation per part drops to 0.10—critical for hitting the $1 target.

Maintenance and repair add 5–8% of equipment 原值 annually. Routine upkeep (lubrication, calibration, replacing spindle bearings) costs 2,000–5,000/year for a 100,000 machine; unexpected failures (e.g., CNC system crashes) can cost 10,000–$30,000. To cut these costs: implement preventive maintenance schedules (e.g., monthly lubrication, quarterly calibration) to reduce breakdowns by 40%; train operators to perform basic tasks (e.g., filter replacement) instead of hiring specialists; source non-OEM replacement parts (e.g., Chinese-made spindle bearings for 30% less than 原厂 parts) without compromising quality.

1.2 Material Costs (200 words)

Materials make up 30–40% of part costs, so strategic selection is key. For non-critical parts, choose low-cost materials that meet performance needs: plastic (e.g., ABS at 2–3/kg) instead of aluminum (2.5–4/kg) for lightweight, non-structural components; low-carbon steel (Q235 at 0.8–1.5/kg) instead of high-strength alloy steel (3–6/kg) for parts with moderate load requirements. For example, a plastic bracket (ABS) costs 0.30 in material, vs. 0.50 for an aluminum equivalent—saving $0.20/part.

Sourcing and waste reduction further lower costs. Buy materials in bulk: ordering 10 tons of aluminum instead of 1 ton secures a 5–10% discount (e.g., 3/kg vs. 3.30/kg). Use nesting software (e.g., SolidWorks Nesting) to arrange parts on raw material sheets—this boosts material utilization from 70% (manual nesting) to 90%+, cutting waste by 20%. For a part using 0.1kg of aluminum, 90% utilization reduces material cost from 0.33 to 0.30/part.

1.3 Labor Costs (200 words)

Labor contributes 15–25% of part costs, tied to skill levels and workforce efficiency. Entry-level operators earn 15–20/hour (basic machine operation), mid-level (programming + setup) 25–35/hour, and senior (5-axis expertise) 40–50/hour. Training can bridge this gap: a 2-week training program on CAD/CAM software (e.g., Mastercam) can turn an entry-level operator into a mid-level contributor, increasing their output by 30% (from 50 parts/hour to 65 parts/hour) without raising wages.

Workforce optimization avoids overstaffing. For example, a shop with 3 CNC mills can assign 1 operator to run 2 machines (via automated tool changers and in-process monitoring), reducing labor per part from 0.40 (1 operator/machine) to 0.27. Scheduling overtime during peak demand (instead of hiring extra staff) also cuts costs—overtime pay (22.5–30/hour) is cheaper than adding a full-time employee (with benefits costing 30% of salary).

1.4 Overhead Costs (100 words)

Overhead (factory rent, utilities, insurance) adds 10–15% of part costs. To reduce these: share factory space with complementary businesses (e.g., a CNC shop sharing a 10,000 sq. ft. space with a 3D printing service) to cut rent by 50% (from 5,000/month to 2,500/month); install energy-efficient equipment (e.g., LED lighting, variable-frequency drives for mills) to lower electricity bills by 20–25%; compare insurance providers annually—switching to a specialist manufacturing insurer can reduce liability coverage costs by 15%.

Part 2: Strategies to Reduce CNC Machining Parts Costs Below $1 (1200 words)

2.1 Design for Manufacturability (DFM) (300 words)

DFM is the most impactful strategy for cost reduction, as design decisions drive 70% of manufacturing costs. Simplifying part geometry eliminates unnecessary machining steps: for example, a part with 5 separate curved surfaces (requiring 10 minutes of 5-axis machining) can be redesigned to 1 continuous curve (3 minutes of 3-axis machining), cutting labor and equipment costs by 70%. Avoid deep pockets (depth > 3× diameter) or sharp internal corners—these require specialized tools (e.g., long-reach end mills) and slow cutting speeds, increasing machining time by 2–3×. A redesign of a sensor housing to remove a 10mm-deep pocket reduced its cost from 1.20 to 0.85.

Tolerance optimization avoids over-specification. Most non-critical parts (e.g., mounting brackets) only need tolerances of ±0.1mm, which can be achieved with standard 3-axis mills (50,000) instead of high-precision machines (200,000). Tightening tolerances to ±0.01mm adds 0.30–0.50/part in equipment and labor costs. Collaborate with designers to map tolerance requirements to functionality: for a part’s mating surface, ±0.05mm may be necessary, but non-mating surfaces can use ±0.2mm—saving $0.15/part.

2.2 Process Optimization (300 words)

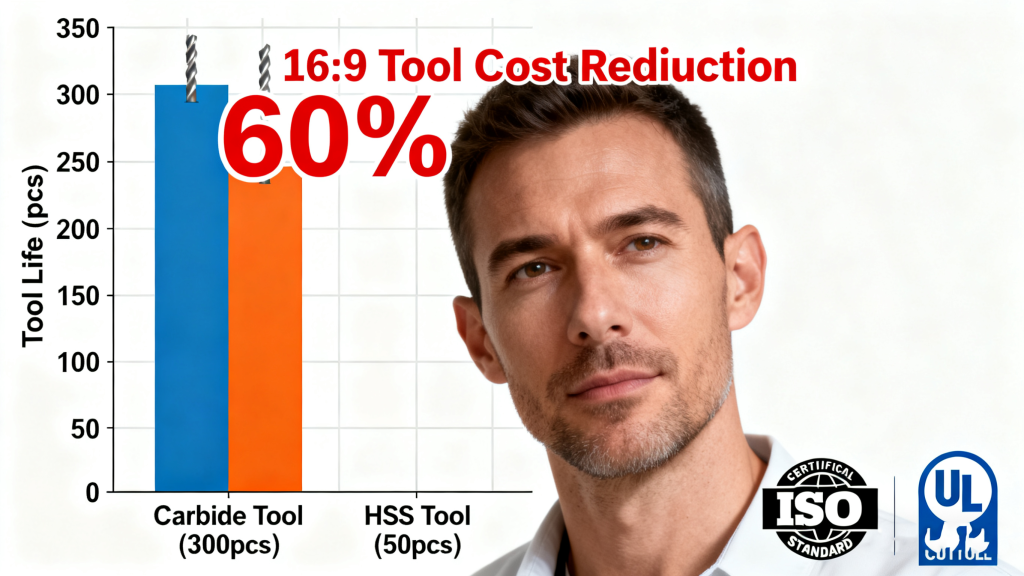

Tool selection and optimization directly cuts machining time. Use carbide tools instead of high-speed steel (HSS): carbide end mills last 5–10× longer (200 parts vs. 20 parts) and allow faster cutting speeds (1,500 rpm vs. 500 rpm), reducing machining time by 60%. While carbide tools cost 3× more (15 vs. 5), their longer life lowers tool cost per part from 0.25 to 0.09.

Tool-path optimization via CAD/CAM software (e.g., Fusion 360) eliminates wasteful movements: for example, reducing empty tool travel (from 20% of total time to 5%) cuts machining time per part from 2 minutes to 1.7 minutes. Use high-speed machining (HSM) strategies for aluminum—this increases feed rates by 50% (from 100 mm/min to 150 mm/min) without compromising quality, further reducing time.

Batch production leverages economies of scale. Setup time (programming, tool changes, workpiece clamping) for a small batch (100 parts) is 1 hour—adding 0.60/part if labor is 36/hour. For a batch of 1,000 parts, setup cost drops to 0.06/part. Merge small orders: if 3 customers each need 200 of the same bracket, produce 600 at once—saving 0.54/part in setup costs. Even for custom parts, design common features (e.g., standard hole sizes) to allow batch processing of similar components.

2.3 Supplier and Partnership Management (300 words)

Supplier negotiation secures lower material and tool costs. Leverage volume: if you purchase 100 tons of steel annually, ask for a 7–10% discount (e.g., 0.90/kg vs. 1.00/kg)—saving $10,000/year for 100,000 parts (each using 0.1kg of steel). Sign long-term contracts (1–2 years) for stable materials (e.g., aluminum) to lock in prices and avoid market fluctuations (which can raise costs by 10–15% in 6 months).

Work with multiple suppliers to create competition: request quotes from 3–5 material vendors, and use the lowest quote to negotiate with your preferred supplier. For tools, partner with distributors that offer volume rebates (e.g., 5% rebate on annual tool purchases over $10,000).

Sub-contracting non-core operations reduces costs. For example, heat treatment (critical for high-strength parts) can be sub-contracted to specialists for 0.20/part, vs. 0.50/part if done in-house (due to equipment and labor costs). Surface finishing (e.g., anodizing) is another prime candidate—sub-contractors with dedicated lines can process parts 30% cheaper than in-house setups. Ensure sub-contractors meet quality standards by conducting regular audits and setting defect rate penalties (<1% defect rate required).

2.4 Continuous Improvement and Lean Manufacturing (300 words)

Kaizen and 5S principles eliminate waste. 5S (Sort, Set in Order, Shine, Standardize, Sustain) organizes the shop floor: sorting tools to remove obsolete ones, setting tools in labeled bins, and standardizing workstations reduce time spent finding tools from 10 minutes/hour to 2 minutes/hour—boosting operator productivity by 13%. Kaizen events (monthly team meetings to identify inefficiencies) can uncover small but impactful changes: for example, relocating raw material storage near machines cuts material handling time by 20%, saving $0.05/part.

KPI monitoring tracks progress and identifies gaps. Key metrics to monitor include:

Production time per part: Target a 10% reduction every 6 months (e.g., from 2 minutes to 1.8 minutes).

Scrap rate: Aim for <2% (down from 5% for unoptimized processes)—each 1% reduction saves 0.03/part (for a 3 material cost).

Machine utilization: Increase from 60% (typical for small shops) to 80% by scheduling preventive maintenance during off-hours and merging small batches.

Use software (e.g., ERP systems like Fishbowl) to automate KPI tracking. For example, a shop monitoring scrap rate found that 40% of defects came from a worn end mill—replacing it proactively cut scrap rate from 3% to 1.5%, saving $0.04/part.

FAQs (300 words)

1. Can reducing costs compromise the quality of CNC-machined parts?

Not if done strategically. Cost reduction should focus on eliminating waste, not cutting critical quality steps. For example, optimizing tool paths reduces machining time without affecting precision; using carbide tools (higher upfront cost but longer life) improves surface finish while lowering tool cost per part. However, avoid compromising on material quality (e.g., using substandard steel) or skipping quality checks (e.g., skipping dimensional inspections) — these lead to costly reworks (up to 5/part) and lost customer trust. A Michigan-based shop reduced costs to 0.90/part while maintaining a 0.5% defect rate by focusing on DFM and process optimization.

2. How long does it take to see the results of cost-reduction strategies?

Immediate results come from quick wins: tool-path optimization and material nesting can reduce costs by 5–10% within 1–2 weeks. Medium-term strategies (DFM, supplier negotiation) take 1–3 months—redesigning parts requires collaboration with designers, and negotiating contracts takes time. Long-term strategies (lean manufacturing, KPI monitoring) deliver 15–20% cost reduction over 6–12 months, as they require cultural and process changes. A California shop saw costs drop from 1.30 to 0.95/part in 4 months: 10% from tool optimization, 15% from DFM, and 5% from supplier discounts.

3. Is it possible to reduce the cost of custom-designed CNC-machined parts to below $1?

Yes, with targeted adjustments. First, apply DFM: simplify custom geometries (e.g., replace custom threads with standard sizes) and relax non-critical tolerances. Second, batch similar custom parts: if a customer orders 50 custom brackets, combine with 150 similar brackets from another customer to spread setup costs. Third, use low-cost materials: for non-structural custom parts, use ABS plastic instead of aluminum. A Texas shop reduced a custom sensor housing’s cost from 1.40 to 0.92/part by: redesigning to remove 2 curved surfaces (saving 0.20), batching with 200 similar parts (saving 0.18), and switching to ABS (saving $0.10).

LSI and NLP Keywords and Related Vocabulary

LSI Keywords

Cost-reduction strategies for CNC machining parts

CNC machining equipment cost management

Material cost control in CNC part production

Labor cost optimization for CNC-machined parts

Design for manufacturability to reduce CNC part costs

Process optimization for low-cost CNC machining

NLP Keywords

How to cut CNC machining part costs

Lowering CNC machining part prices

Strategies to make CNC-machined parts affordable

Cost-effective CNC part production methods