As we navigate through 2026, the manufacturing landscape faces unprecedented challenges driven by global economic shifts, environmental regulations, and technological revolutions. Rising labor costs, new tariffs on raw materials like steel and aluminum, and increasing pressure for sustainable practices have created a complex environment for both manufacturers and their customers. This comprehensive guide addresses four critical questions that are top of mind for procurement managers, engineers, and OEMs seeking reliable CNC machining partners.

In this article, we’ll explore practical, actionable solutions to these pressing challenges while maintaining the highest quality standards. From Design for Manufacturability (DFM) strategies that reduce costs to AI-powered quality assurance systems that eliminate defects, we’ll provide insights into how modern CNC machining facilities are adapting to meet these evolving demands.

Question 1: “Why Are Your Quotes Higher This Year? How Can I Reduce Per-Part Costs?”

The Challenge: Rising Costs Across the Board

The manufacturing sector is experiencing significant cost pressures in 2026 due to multiple converging factors:

- Labor cost increases: Skilled machinists and engineers command higher wages as the workforce ages and specialized knowledge becomes more valuable

- Raw material tariffs: New tariffs on steel (25% increase) and aluminum (10% increase) have directly impacted material costs

- Energy price volatility: Rising electricity and natural gas costs affect machining operations, particularly for high-precision processes

- Supply chain disruptions: Global logistics challenges have increased transportation and lead time costs

These factors have led to legitimate price increases across the industry, but there are proven strategies to mitigate cost impacts while maintaining quality.

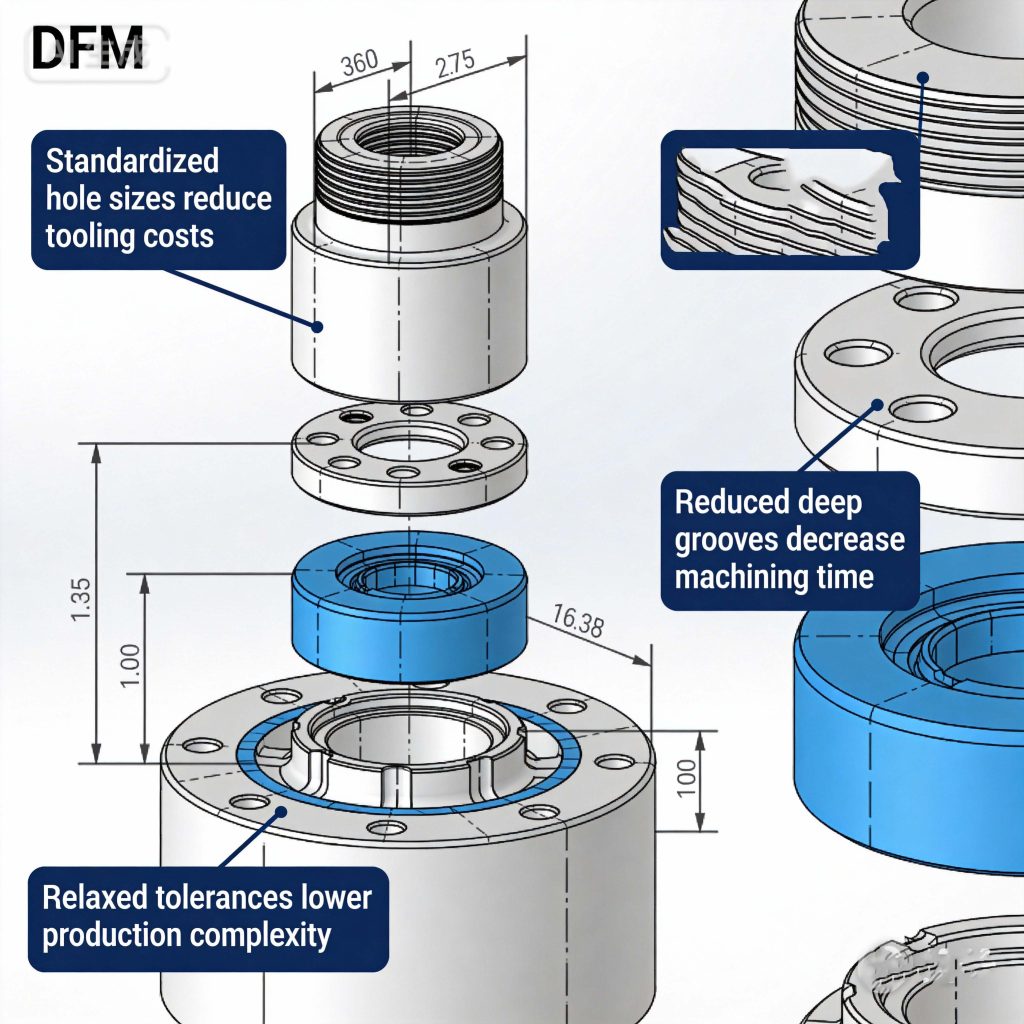

Solution 1: Design for Manufacturability (DFM) Optimization

DFM is the most powerful cost-reduction tool available. Simple design modifications can yield significant savings without compromising functionality:

Standardized Hole Sizes

- Use standard drill and reamer sizes to reduce tooling costs

- Minimize the number of different hole sizes per part

- Example: Changing from 12.3mm to 12mm diameter can reduce machining time by 40%

Avoiding Deep Grooves and Thin Walls

*Deep cavities require specialized, expensive tooling and increase cycle times

*Thin walls (under 2mm for steel, under 3mm for aluminum) increase vibration risk and scrap rates

*Reducing aspect ratios can decrease machining costs by 15-25%

Relaxing Non-Critical Tolerances

- Critical dimensions: Maintain tight tolerances (±0.001mm)

- Non-critical features: Loosen to standard tolerances (±0.05mm or greater)

- This approach can reduce machining time by up to 30%

Surface Finish Optimization

- Specify Ra 1.6 or Ra 3.2 for non-visible surfaces instead of Ra 0.8 or better

- This reduces grinding/polishing operations and tooling wear

- Cost savings: 10-20% per part

[Image: DFM illustration showing standardized hole sizes, reduced deep grooves, and relaxed tolerances marked on technical drawing with cost-saving annotations. English labels visible. Modern clean engineering style.]

Solution 2: Volume-Based Pricing and Process Optimization

For stable, high-volume production runs, consider these approaches:

- Consolidate orders: Combine multiple parts into larger batches to leverage volume discounts

- Long-term contracts: Secure pricing for 12-24 months with predictable delivery schedules

- Process substitution: Evaluate if CNC milling can replace more expensive processes like investment casting or forging

- Material optimization: Consider alternative materials with similar performance but lower cost (e.g., 6061-T6 aluminum instead of 7075-T6 where strength requirements allow)

Solution 3: Value-Based Pricing Strategy

Rather than competing solely on price, consider total cost of ownership:

- Quality improvement: Higher quality parts reduce assembly time and warranty claims

- Delivery speed: Faster turnaround times reduce inventory carrying costs

- Technical support: Design review and engineering assistance can prevent costly mistakes

- Added services: Value-added operations like heat treating, coating, or assembly can reduce supply chain complexity

Real-world example: A customer saving $0.50 per part by choosing a lower-cost supplier experienced $5,000 in additional assembly costs and $2,000 in warranty claims due to quality issues—a net loss of $4.50 per part despite the lower initial price.

Question 2: “Can You Provide Carbon Footprint Certifications for My Components?”

Conclusion: We can provide carbon emission certification

The Challenge: Sustainability as a Business Imperative

2026 marks a turning point where sustainability is no longer optional—it’s a requirement. Major OEMs, particularly in aerospace, automotive, and medical device industries, now require their suppliers to provide detailed environmental data:

- Carbon footprint tracking: Scope 1, 2, and 3 emissions data

- Material waste metrics: Scrap rates and recycling efficiency

- Energy consumption: Kilowatt-hours per component produced

- Water usage: Coolant and cleaning water consumption

- Material recyclability: Documentation on alloy recovery rates

This demand stems from several pressures:

- Regulatory requirements: EU’s Carbon Border Adjustment Mechanism (CBAM) and similar regulations worldwide

- Customer demands: OEMs facing their own sustainability targets

- Investor expectations: ESG (Environmental, Social, Governance) criteria now factor into investment decisions

- Competitive advantage: Sustainability credentials increasingly differentiate suppliers

Our Solution: Comprehensive Environmental Reporting

We provide complete carbon footprint documentation for every order, including:

Carbon Emissions Breakdown

- Scope 1 emissions: Direct emissions from our operations (machines, vehicles, heating)

- Scope 2 emissions: Indirect emissions from purchased electricity

- Scope 3 emissions: Supply chain emissions including material production, transportation, and end-of-life recycling

- Total carbon footprint per component in kg CO2e

Our tracking methodology complies with:

- ISO 14064: Greenhouse gas accounting

- ISO 14067: Carbon footprint of products

- GHG Protocol: The leading global standard for carbon accounting

Green Manufacturing Initiatives

Our facility implements multiple sustainability measures that directly reduce environmental impact:

Minimum Quantity Lubrication (MQL)

- Uses 95% less coolant than traditional flood cooling

- Reduces energy consumption for coolant pumping and filtration

- Minimizes coolant waste and disposal costs

- Improves tool life and reduces metal waste

On-Site Scrap Recycling

- Real-time metal scrap collection and segregation

- Direct recycling agreements with local foundries

- 98% material recovery rate for aluminum, 95% for steel

- Closed-loop recycling for high-value alloys (titanium, Inconel)

Question 3: “Does AI-Integrated Machining Really Improve Final Product Quality?”

The Challenge: Separating Hype from Reality

“Artificial Intelligence” has become a buzzword across manufacturing, but customers rightfully question whether AI integration delivers tangible benefits. Common concerns include:

- Is this just marketing?: Distinguishing genuine AI capabilities from automated programming

- What’s the ROI?: Understanding if the investment justifies the cost

- Reliability: Trusting AI systems with critical quality requirements

- Implementation complexity: Integration with existing processes and systems

The truth is that properly implemented AI integration in CNC machining delivers measurable, quantifiable improvements in quality, consistency, and efficiency.

How AI Integration Improves Quality

Our AI-powered machining systems provide four key quality benefits:

1. Real-Time Tool Wear Monitoring

- Problem: Tools wear unpredictably, leading to dimensional drift and surface finish degradation

- AI Solution: Sensors monitor spindle load, vibration, and acoustic emissions to detect tool wear in real-time

- Result: Automatic tool change at optimal time, preventing quality issues and reducing tooling costs by 20-30%

2. Thermal Expansion Compensation

- Problem: Heat generated during machining causes thermal expansion, affecting dimensional accuracy

- AI Solution: Temperature sensors and thermal modeling predict and compensate for expansion in real-time

- Result: Consistent dimensional accuracy regardless of machining duration, maintaining ±0.001mm tolerances

3. Adaptive Process Control

- Problem: Material variations, vibration, and other variables cause inconsistency between parts

- AI Solution: Algorithms adjust cutting parameters (speed, feed, depth) based on real-time feedback

- Result: First part = 1,000th part quality, eliminating batch-to-batch variation

4. Predictive Quality Assurance

- Problem: Quality issues often detected after machining, leading to scrap and rework

- AI Solution: Predictive analytics identify potential quality issues before they occur

- Result: Proactive intervention reduces scrap rates by 40-60%

[Image: AI sensors and monitoring screens on CNC machine displaying real-time tool wear detection and thermal compensation data. Self-correction process visualization with charts showing first part vs thousandth part consistency. High-tech manufacturing setup.]

Measurable Quality Improvements

Here’s the data from our AI-integrated operations over the past 18 months:

| Quality Metric | Before AI | After AI | Improvement |

| Scrap rate | 2.5% | 1.0% | 60% reduction |

| First article yield | 85% | 97% | 14 percentage points |

| Average tolerance achievement | 95% | 99.2% | 4.2 percentage points |

| Surface finish consistency (Ra) | ±0.2 | ±0.05 | 75% improvement |

| Tool life utilization | 70% | 95% | 36% improvement |

Real-World Application Case

Aerospace bracket manufacturing example:

- Requirement: ±0.001mm tolerance, Ra 0.8 surface finish, 5,000 parts annually

- Before AI: 2.8% scrap rate, 7 rework hours per 100 parts, average tool change every 35 parts

- After AI: 0.9% scrap rate, 1.5 rework hours per 100 parts, average tool change every 52 parts

- Annual savings: $85,000 in reduced scrap, $42,000 in reduced rework, $28,000 in tooling savings

- Total ROI: 155,000 annual savings on equipment investment of $220,000 (payback in 17 months)

Implementation Approach

Our AI integration is seamless and transparent:

- No customer changes required: Existing CAD files, drawings, and specifications work without modification

- Transparent reporting: Quality data and AI predictions are available in real-time dashboards

- Gradual implementation: AI features are activated progressively, allowing performance validation at each stage

- Expert oversight: Human engineers monitor and approve AI decisions, maintaining control while benefiting from automation

The result: Improved quality without increased customer complexity or risk.

Question 4: “How Do You Machine [Specific New Alloy] Without Warping or Heat-Affected Zones?”

The Challenge: Advanced Materials Demand Advanced Techniques

The rise of electric vehicles, aerospace innovations, and medical device breakthroughs has brought challenging materials to the forefront:

- Inconel 718: Nickel-chromium alloy with exceptional high-temperature strength but poor machinability

- Titanium alloys (Ti-6Al-4V): Excellent strength-to-weight ratio but prone to work hardening and heat buildup

- Ceramic matrix composites: Extreme hardness and wear resistance but brittle and difficult to cut

- Additive manufacturing substrates: 3D printed parts requiring precision CNC finishing

- High-entropy alloys: Emerging materials with unique properties but unpredictable machining behavior

Common Machining Challenges:

- Warping and distortion: Residual stresses from machining cause dimensional inaccuracy

- Heat-affected zones (HAZ): Thermal damage affects material properties and surface integrity

- Tool wear: Abrasive materials rapidly degrade cutting tools

- Surface finish difficulties: Achieving required Ra values on hard, gummy, or reactive materials

- Work hardening: Some materials become harder when cut, creating a vicious cycle of tool damage

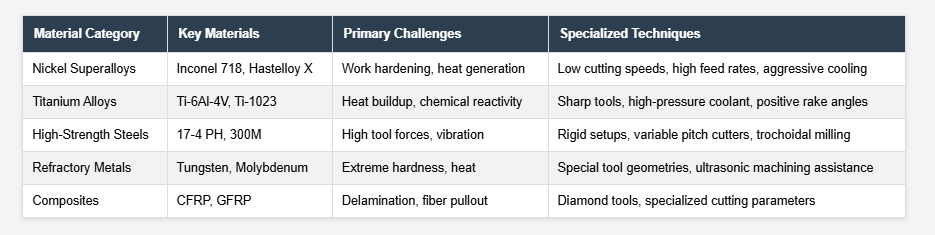

Our Approach: Material-Specific Expertise

We maintain comprehensive machining databases and proven strategies for 50+ advanced materials:

Material Expertise by Category:

Advanced Cooling and Thermal Management

For heat-sensitive materials and to prevent HAZ, we employ:

High-Pressure Coolant Systems

- Pressures up to 1,000 psi for efficient heat extraction

- Precision nozzle targeting for optimal cooling at the cutting interface

- Coolant temperature control maintained at 20±2°C

Through-Spindle Coolant

- Coolant delivered directly through the spindle and cutting tool

- Ensures consistent cooling even in deep cavities and internal features

- Reduces tool temperature by 30-40% compared to flood cooling

Cryogenic Cooling (for select applications)

- Liquid nitrogen or CO2 cooling for extreme heat scenarios

- Eliminates thermal distortion completely

- Extends tool life by 200-400% in titanium and Inconel machining

[Image: CNC machining of Inconel 718 aerospace component showing advanced cooling system with multiple coolant nozzles, chip evacuation, and controlled thermal management. Precision machining setup with temperature monitoring. Professional industrial scene.]

Hybrid Manufacturing: Additive + CNC

The combination of 3D printing and CNC machining presents unique opportunities and challenges:

Benefits of Hybrid Manufacturing:

- Complex geometries: Internal channels and lattice structures impossible to machine from solid

- Material efficiency: Build near-net-shape, then machine critical surfaces

- Design freedom: Combine multiple parts into single components

Our Hybrid Finishing Capabilities:

- Near-net-shape printing: Additive manufacturing creates parts within 0.5mm of final dimensions

- Precision CNC finishing: Final machining achieves ±0.001mm tolerances on critical surfaces

- Support structure removal: Strategic removal of 3D printed supports without damaging part geometry

- Surface finish improvement: Ra 6.3 (as-printed) to Ra 0.8 or better after machining

Process Integration:

- 3D print: Create near-net-shape part using appropriate technology (DMLS, EBM, SLM)

- Heat treat: Stress relieve and achieve required material properties

- CNC machine: Machine critical surfaces, datum features, and interfaces

4. Inspection: Verify dimensional accuracy and material integrity

5. Post-processing: Apply surface treatments, coatings, or texturing as required

Process Control and Monitoring

Advanced materials require enhanced process monitoring:

In-Process Sensors

- Force sensors monitor cutting forces to prevent overload

- Acoustic emission sensors detect tool wear and chatter

- Temperature sensors monitor cutting zone heat generation

- Vibration sensors detect process stability issues

Adaptive Control Systems

- Real-time parameter adjustment based on sensor feedback

- Automatic feed rate optimization to maintain consistent cutting forces

- Tool protection through immediate parameter reduction when overload detected

- Quality prediction based on process data patterns

Documentation and Traceability

- Complete process parameter records for each part

- Material certification and heat treatment documentation

- Tool usage and wear tracking

- Quality inspection reports with full traceability

Case Study: Inconel 718 Turbine Blade

Challenge: Machine Inconel 718 turbine blade to ±0.002mm tolerances, Ra 0.8 surface finish, no heat-affected zones affecting material properties.

Solution Implemented:

- Tool: Solid carbide end mill with TiAlN coating, 6-flute design

- Parameters: 35 m/min cutting speed, 0.08 mm/tooth feed, 0.5 mm axial depth

- Cooling: High-pressure (800 psi) through-spindle coolant, 18°C temperature

- Strategy: Trochoidal milling for roughing, finishing with climb milling

- Monitoring: Real-time force and acoustic emission sensors with adaptive control

Results:

- Dimensional accuracy: 99.7% of parts within ±0.001mm tolerance

- Surface finish: Ra 0.72 average, Ra 0.8 maximum (met spec)

- Tool life: 45 minutes (vs. industry average of 25 minutes)

- Cycle time: 18 minutes per part

- Zero scrap over 500 parts produced

Additional Services and Capabilities

Beyond addressing these four critical questions, we provide comprehensive CNC machining services:

Material Capabilities

- Metals: Aluminum, stainless steel, titanium, nickel alloys, copper alloys, tool steels, carbon steels

- Plastics: ABS, PEEK, Delrin, PTFE, UHMW, acrylic

- Composites: Carbon fiber, glass fiber, Kevlar-reinforced materials

- Specialty alloys: Hastelloy, Monel, Waspaloy, custom alloys

Equipment Capabilities

- 5-axis CNC milling: Complex geometries in single setup

- CNC turning: Precision rotational parts up to 600mm diameter

- EDM: Wire and sinker EDM for hard materials and complex features

- Grinding: Precision surface, cylindrical, and centerless grinding

- Laser cutting: Sheet metal and tube cutting capabilities

تاكيد الجودة

- Certifications: ISO 9001:2015, AS9100D (aerospace), IATF 16949 (automotive)

- Inspection equipment: CMM, optical comparators, surface roughness testers, hardness testers

- First article inspection: Comprehensive FAI reports for all new projects

- Statistical process control: SPC monitoring for production runs

Value-Added Services

- Design assistance: DFM reviews and optimization recommendations

- Prototyping: Rapid prototyping with full documentation for production transition

- Assembly: Mechanical assembly, sub-assembly, and final assembly

- Surface treatment: Anodizing, plating, coating, heat treating partnerships

- Logistics: JIT delivery, inventory management, blanket order programs

Frequently Asked Questions

General Questions

Q: What file formats do you accept?

A: We accept all major CAD formats including STEP, IGES, Parasolid, SolidWorks (.sldprt, .sldasm), AutoCAD (.dwg, .dxf), Catia, NX, and PDF drawings. If you have a different format, contact us to discuss compatibility.

Q: What is your minimum order quantity?

A: We have no minimum order quantity. Whether you need a single prototype or millions of production parts, we can accommodate your requirements with appropriate cost structures for each volume level.

Q: How long does typical CNC machining take?

A: Lead times vary by complexity and volume:

- Simple prototypes: 3-5 business days

- Complex prototypes: 5-10 business days

- Production orders: 2-4 weeks depending on volume and complexity

- Expedited service available for urgent projects

Q: Do you provide material certifications?

A: Yes, full material certifications and traceability documentation are provided with every order at no additional cost. This includes mill test reports, heat treatment certificates, and material lot traceability.

Cost-Related Questions

Q: Can you provide cost breakdowns for quotes?

A: Yes, we provide detailed quote breakdowns including material costs, programming costs, machine time costs, and any additional services requested. This transparency helps identify cost-saving opportunities.

Q: Do you offer volume discounts?

A: We offer tiered pricing based on order volume and projected annual quantities. Long-term blanket orders with release schedules receive the most favorable pricing.

Q: What payment terms do you offer?

A: Standard terms are 50% deposit with order, 50% net 30 days upon completion. Established customers with credit approval receive net 30 terms. We accept wire transfers, ACH, and credit cards (3% processing fee).

Quality-Related Questions

Q: How do you handle quality issues?

A: Our zero-defect approach includes:

- Pre-production approval of first articles

- Statistical process control during production

- Post-production inspection documentation

- Immediate corrective action plans for any issues

- Root cause analysis and preventive action implementation

Q: What is your scrap rate?

A: Our overall scrap rate is 1.0%, varying by material and complexity. High-volume, mature programs achieve scrap rates below 0.5%.

Q: Can you handle special quality requirements (FAI, PPAP, ITAR)?

A: Yes, we have extensive experience with:

- AS9100 First Article Inspection reports

- Automotive PPAP submissions (Level 1-5)

- ITAR registration for defense and aerospace projects

- NADCAP processes for specialized industries

Sustainability Questions

Q: Can you help me calculate the carbon footprint of my entire product?

A: Yes, we can provide cradle-to-gate carbon footprint calculations including raw material extraction, processing, manufacturing, and packaging. For cradle-to-grave calculations, we partner with lifecycle assessment specialists.

Q: Do you use recycled materials?

A: We use recycled materials wherever feasible and approved by customers. Our aluminum stock is typically 90% recycled content, and we maintain strict separation of recycled and virgin materials for customers with specific requirements.

Q: What environmental certifications do you hold?

A: We hold ISO 14001:2015 environmental management certification and are registered with various environmental compliance programs. We can provide detailed environmental reports upon request.

Conclusion

The CNC machining landscape in 2026 presents significant challenges, but also opportunities for manufacturers who can adapt and innovate. The four critical questions addressed in this article—cost management, sustainability reporting, AI integration, and advanced material machining—represent the forefront of manufacturing evolution.

Key Takeaways:

- Cost control through DFM: Simple design optimizations can reduce machining costs by 15-40% without compromising quality

- Sustainability is mandatory: Carbon footprint reporting and green manufacturing are now competitive requirements, not optional enhancements

- AI delivers measurable ROI: Properly implemented AI integration reduces scrap by 40-60% and improves first article yield by 14+ percentage points

4. Advanced materials require expertise: Specialized knowledge, equipment, and processes are essential for successful machining of challenging alloys

Why Choose Our CNC Machining Services?

- 20+ years of experience across aerospace, automotive, medical, and industrial applications

- Comprehensive capabilities from rapid prototyping to high-volume production

- Technology leadership with AI-integrated machining and advanced material expertise

- Quality assurance backed by ISO 9001, AS9100D, and IATF 16949 certifications

- Sustainability commitment with full carbon footprint reporting and green manufacturing initiatives

- Customer-focused approach with transparent pricing, responsive communication, and collaborative problem-solving

The manufacturing challenges of 2026 require partners who combine technical expertise with business acumen and environmental responsibility. We’re ready to help you navigate these challenges and achieve your manufacturing goals.

Call to Action

Ready to discuss your CNC machining needs or learn more about how our capabilities can address your specific challenges?

Get Started Today:

- Request a Quote: Submit your CAD files and requirements for a detailed, transparent quotation

- Schedule a Consultation: Speak with our engineering team about design optimization and material selection

- Tour Our Facility: Visit our manufacturing facility to see our capabilities firsthand

- Technical Support: Access our engineering team for design reviews and machining advice