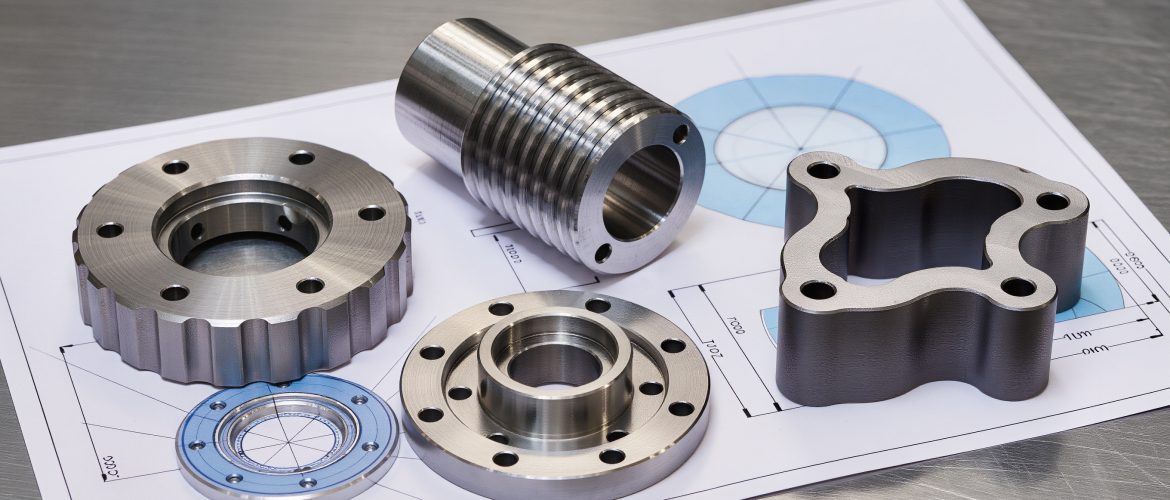

Precision CNC machining OEM mass customization:we generate 100000 to 1 million products for customers every year!

The advantages of batch OEM production

We have been deeply involved in the field of CNC machining and foreign trade for more than 20 years, focusing on providing high-precision and large-scale OEM batch production solutions for global customers. With advanced equipment, standardized processes, and full chain service capabilities, we can efficiently undertake bulk orders for various metal and non-metal components. From drawing optimization, sample making to mass production delivery, cross-border after-sales support, we assist customers in seizing opportunities in overseas markets and upgrading product competitiveness.

One、 Why mass produce and what benefits does mass production bring to you?

- Reduce costs and increase efficiency, enhance market competitiveness

Large scale production significantly reduces unit processing and management costs, and compared to small-scale decentralized processing, can save customers 15% -30% of production costs; Full chain services save customers the time and cost of coordinating design, processing, logistics, and other aspects. With stable delivery cycles (7-45 working days), they help customers quickly respond to market demand and seize pricing and delivery opportunities.

- Controllable quality, reducing after-sales losses

High precision technology and full process quality control ensure product consistency, avoid assembly failures, returns, rework, and other issues caused by size deviations and performance problems, and reduce after-sales maintenance and loss costs. At the same time, the inspection report is delivered with the goods, providing support for customer product traceability and market compliance, especially suitable for industries such as automobiles and medical devices that require high quality.

- Focus on the core and reduce operational pressure

Outsourcing non core component processing to us allows customers to focus on product research and development, brand operation, and market expansion without the need to invest heavily in purchasing equipment, building production lines, and cultivating technical teams. This significantly reduces the difficulty of fixed asset investment and operational management, and enhances the core business competitiveness of the enterprise.

- Flexible adaptation to respond to market changes

The order volume can be adjusted according to customer market demand, supporting seamless integration between small-scale trial production (minimum order of 200 pieces) and large-scale mass production, helping customers avoid inventory backlog risks; Simultaneously respond quickly to product design iteration requirements, optimize processing technology, assist customers in quickly launching upgraded products, and adapt to market dynamic changes.

- Cross border worry free, expanding global markets

Our professional cross-border service team provides full support throughout the entire process, from order negotiation, document preparation to customs clearance and delivery, solving cross-border problems such as language communication, trade rules, and logistics timeliness. A mature global logistics cooperation system can ensure timely delivery of products, helping customers easily expand overseas markets without worrying about supporting matters beyond processing.

The advantages of batch OEM production

Two、 Why choose us?

- Large scale production capacity reserve, undertaking large batch orders

Equipped with 100 sets of imported CNC machining equipment (CNC lathes, machining centers, milling machines, wire cutting, etc.), a modern assembly line production workshop is built, with a monthly production capacity of over 500000 precision parts. Through scientific capacity planning and supply chain scheduling, it is possible to flexibly undertake orders ranging from thousands to millions of pieces, while relying on economies of scale to compress unit production costs, providing customers with cost-effective and market competitive quotations that balance batch demand and cost control.

- High precision process control to ensure batch consistency

The core equipment is selected from international first-line brands such as HAAS and DMG MORI, combined with high-precision detection equipment such as Zeiss coordinate measuring instrument and Mitutoyo projector. The machining tolerance can be accurately controlled within ± 0.005mm. Establish a dedicated process database and solidify parameters for different materials such as aluminum alloy, stainless steel, titanium alloy, and engineering plastics. Reduce manual intervention through automated programming to ensure that the size, accuracy, and performance of each batch of products are completely consistent and strictly comply with customer drawing standards and industry norms.

- Full chain OEM service, adapted to diverse scene requirements

We provide one-stop services from pre design optimization, process customization, sample making, mass production, surface treatment (anodizing, electroplating, heat treatment), packaging and transportation. Based on the 2D/3D drawings, samples, or requirement descriptions provided by customers, the product structure can be optimized to enhance processing feasibility and stability. At the same time, customized solutions can be developed in accordance with the compliance requirements of different industries such as automotive, electronics, and medical devices, without the need for customers to coordinate multiple resources.

- Strict quality system, building a solid quality defense line

First to pass ISO9001:2015 and IATF16949 (automotive industry) quality certification, some products can provide FDA certification (medical device field), and establish a “incoming material process finished product” three inspection control system. Before the raw materials are stored, the material certification and specifications are checked. During the processing, real-time online detection and parameter adjustment are carried out. In the finished product stage, full inspection is carried out and a dedicated report is issued. The defect rate is strictly controlled below 0.3% to ensure that the delivered products are 100% qualified.

- Cross border service capability, connecting the global delivery chain

Integrate high-quality supply chain resources, establish long-term cooperation with global raw material suppliers and surface treatment manufacturers, and quickly allocate materials to avoid production delays. At the same time, we have deep cooperation with well-known logistics companies such as DHL, FedEx, Maersk, etc., providing flexible logistics solutions such as sea freight, air freight, and door-to-door, covering mainstream overseas markets such as Europe, America, Southeast Asia, and the Middle East. Our dedicated foreign trade team is proficient in multilingual communication and cross-border trade rules, and can assist in handling customs clearance, certificates of origin, and other matters to avoid trade risks.

Three、 Standardized OEM batch production process, transparent and controllable throughout the entire process

- Requirement docking and evaluation:Customers provide product drawings, batch requirements, material accuracy, surface treatment, and delivery time information. Our foreign trade and technical teams jointly evaluate feasibility and provide preliminary quotations and process suggestions within 12 hours to efficiently respond to requirements.

- Plan confirmation and signing:Based on customer needs, optimize processing technology and production plans, calculate accurate costs, and sign a formal OEM contract, clarifying core terms such as quality standards, delivery milestones, and payment methods to protect the rights and interests of both parties.

- Sample making and acceptance:Prioritize the production of 1-5 samples, which will be sent to the customer after passing the full inspection. Adjust the process parameters according to feedback until the sample acceptance is passed, and lock in the batch production standard.

- Batch production and process control: Start large-scale production, assign dedicated personnel to conduct full process inspections and synchronize production progress in real time, strictly follow established processes and quality standards, and ensure that production efficiency and product quality meet both standards.

- Finished product inspection and packaging: After all finished products pass the inspection, anti-static, moisture-proof, customized pallets and other packaging methods are used according to the product characteristics, with clear labeling to avoid damage during cross-border transportation.

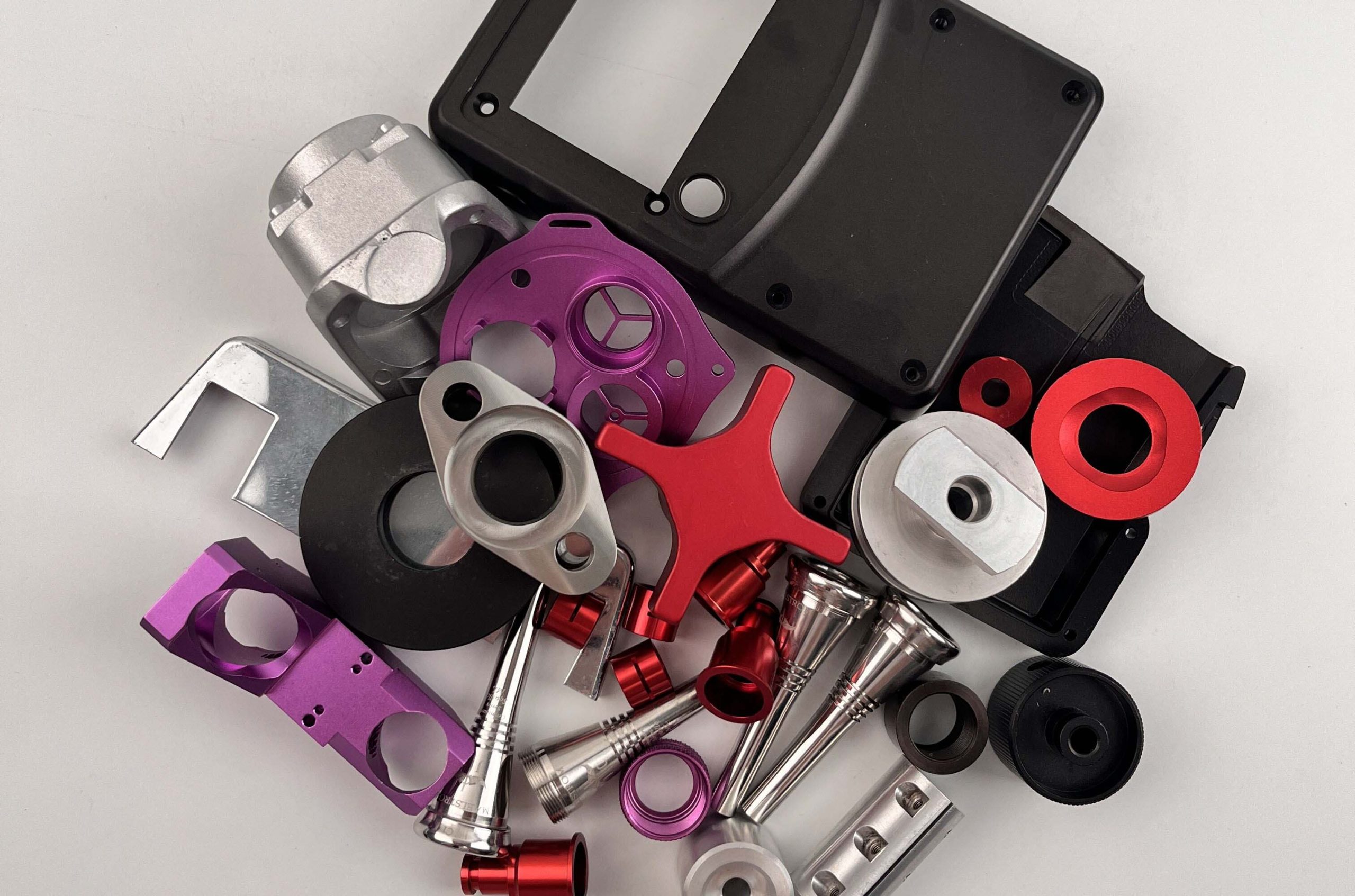

- Cross border delivery and after-sales service:Arrange logistics delivery and provide tracking information according to the contract, provide quality assurance services after product delivery, and respond promptly to customer inquiries and after-sales needs during use.Four、 Applicable industries and core processed productsAdapt to the industryWidely serving the fields of automobile manufacturing, electronic appliances, medical equipment, aerospace, communication equipment, smart homes, robots, engineering machinery, etc., it can meet the batch processing needs of precision components in various industries.Core processed productsMetal components: robot parts, automotive parts, aircraft parts, photovoltaic parts, drone parts, brackets, shells, precision connectors, artificial intelligence product parts, etc;Non metallic components: POM, PC, ABS, PEEK and other engineering plastic processing parts, insulation parts, wear-resistant parts, etc;

Customized components: Integrated processing components and assembly parts specially customized according to customer drawings.

Five、 Core equipment and quality certification

Quality certification system

ISO9001:2015 quality management system certification, IATF16949 automotive industry quality certification, CE certification, RoHS compliance certification, fully comply with overseas market compliance requirements.

Core processing and testing equipment

Device Type brand Processing/Testing Scope Precision grade CNC machining center HAAS VF-2、DMG MORI CMX 50 U X≤1000mm,Y≤500mm,Z≤500mm ±0.005mm CNC lathe HAAS ST-40、OKUMA LB3000 Maximum processing diameter 400mm,length 1000mm ±0.003mm Testing equipment Zeiss Coordinate Measuring Instrument Full size inspection, measurement range≤1000×800×600mm 0.001mm

six、 Overseas cooperation cases (partially confidential)

- Automotive industry: OEM mass production of transmission gear components for well-known European car companies, with a monthly output of 50000 pieces and tolerance control of ± 0.008mm. Passed IATF16949 certification, stable cooperation for more than 3 years, zero quality complaints;

- Electronics industry: Processing aluminum alloy precision connector housings for Southeast Asian electronics manufacturers, matched with anodizing treatment, with a monthly output of 150000 pieces and a stable delivery cycle of 30 working days, suitable for customer assembly line production needs;

- Humanoid robot industry: We produce various parts for Chinese humanoid robot enterprises, with accompanying appearance treatments such as sandblasting, anodizing, etc. We produce 10000 pieces per month and have deep cooperation with customers for many years.Seven、 Frequently Asked Questions (FAQ)

1、What is the minimum order quantity (MOQ)?The minimum order quantity for regular products is 500 pieces, while for special materials and high-precision products, the minimum order quantity can be negotiated up to 200 pieces; The larger the order quantity, the more obvious the unit price advantage, and at the same time, priority production rights can be enjoyed.2、How to ensure the delivery cycle of mass production?According to the order volume and product complexity, the delivery cycle is 30-45 working days: 7-15 days for 500-5000 regular products, 20-30 days for 5000-50000 products, and 30-45 days for 50000 or more products; Urgent orders can be shortened by adjusting production capacity priorities, and specific details can be negotiated and confirmed.3、How to ensure the quality consistency of bulk products?

Through the triple guarantee of “process solidification+automated processing+full inspection traceability”: unified equipment parameters and processing flow, automated programming reduces human errors, 5% of products are randomly selected from each batch for full-size testing, and testing data and samples are retained to achieve quality traceability.

4、What cross-border payment and trade terms are supported?

Payment methods: T/T (30% advance payment, 70% payment before shipment), L/C (letter of credit), Western Union remittance, which can be flexibly adjusted according to the cooperation period; Trade terms: EXW, FOB, CIF, DAP, suitable for different customers’ logistics and customs clearance needs.

- Can customized packaging and brand identity services be provided?

Support customized packaging, and design shockproof, moisture-proof, and anti-static solutions based on product characteristics and transportation needs; We can also provide logo screen printing and laser engraving services, and customers need to provide legal authorization documents to ensure brand compliance.

Immediately connect and initiate exclusive OEM bulk cooperation

If you have a demand for CNC machining OEM batch production, please feel free to provide drawings, samples or detailed requirement descriptions. We will provide professional quotations and process solutions within 24 hours, and become a reliable partner for you to expand overseas markets with precision technology and efficient services.