In 2026’s competitive manufacturing landscape, CNC machining services face an unprecedented challenge: supplier excuses are becoming increasingly sophisticated. “Machine breakdown,” “customs delays,” “material issues”—these familiar refrains often mask deeper systemic problems that can derail your projects and erode your bottom line.

The difference between a successful project and a costly failure often comes down to one critical factor: asking the right questions before you commit. By understanding and preparing for these five hidden risks, you can transform your CNC sourcing from a game of chance into a strategic advantage.

Risk #1: The “Machine Breakdown” Excuse

The Problem

Why This Happens

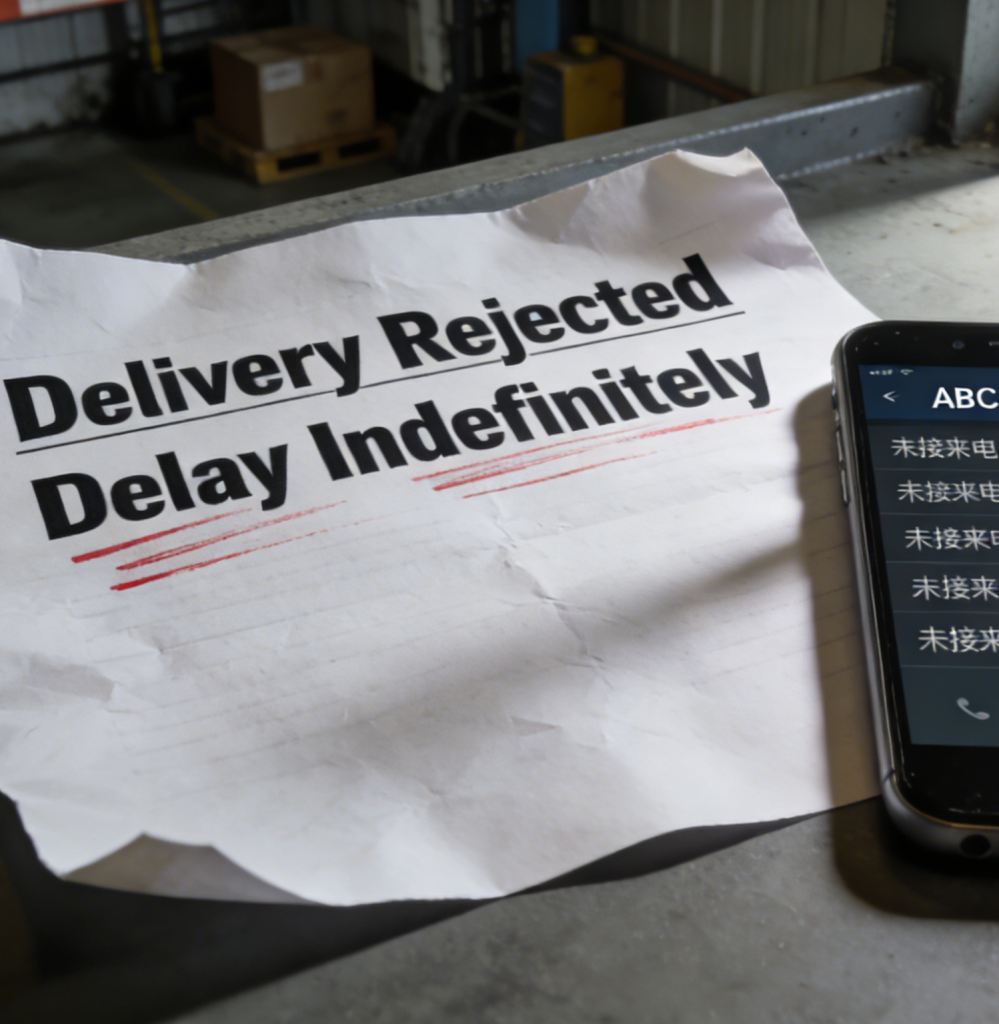

Your supplier delivers late—again. The explanation? “Machine breakdown.” It’s a classic excuse that masks poor production planning and insufficient capacity. When a CNC machining provider relies on breakdown narratives rather than proactive scheduling, your deadlines become casualties of their operational failures.

Why This Happens

Many suppliers operate with minimal backup capacity, running machines at maximum utilization to cut costs. When the inevitable breakdown occurs, there’s no contingency plan. Your orders sit idle while they scramble to reschedule, compromising your production timeline and market opportunities.

The Red Flags to Watch For

Vague explanations about production issues

Frequent, unexplained delays

Reactive rather than proactive communication

No capacity planning discussions upfront

Our Solution: Safety Stock Inventory Program

We’ve eliminated this excuse through our proactive inventory management system. Here’s how we protect your deadlines:

- Demand Forecasting: We work with you to understand your upcoming requirements months in advance

- Pre-Production Storage: We manufacture and store your parts before you need them

- Instant Availability: When you place an order, we ship from inventory—no waiting for machine time

The Result: 98% on-time delivery rate. No more breakdown excuses, no more schedule disruptions.

Risk #2: The “Customs & Local Charges” Battle

The Problem

You’ve negotiated a great price, only to be hit with unexpected import fees, customs delays, and “local charges” that weren’t in the original quote. The transparency you expected disappears behind a maze of international shipping complexities.

Why This Happens

Many overseas suppliers quote “FOB” (Free On Board) prices, intentionally excluding shipping, insurance, customs duties, and local handling fees. By the time your parts arrive, the total cost has ballooned—sometimes by 20-30%—and you have no recourse.

The Red Flags to Watch For

Surprise charges after delivery

Quotes that don’t specify Incoterms clearly

Vague or incomplete shipping terms

Refusal to provide landed cost estimates

Our Solution: Transparent Landed Cost Pricing

We believe in full transparency from day one. No hidden fees, no surprises—ever.

What We Provide Upfront:

- Complete Cost Breakdown: Manufacturing + Shipping + Insurance + Customs Duties + Local Handling

- No Customs Delays: We handle all documentation and compliance requirements

- Fixed Landed Cost: The price we quote is the price you pay—period

Example: For a $10,000 order to the United States:

- Traditional supplier quote: $10,000 (FOB)

- Actual landed cost: $12,500-13,000 (after shipping, duties, fees)

- Our quote: $12,200 (all-inclusive, guaranteed)

The Result: Budget certainty. No more renegotiations, no more surprise invoices.

Risk #3: The Technical “Trap”—Poor Tooling Practices

The Problem

Your parts arrive with surface roughness issues, chatter marks, or inconsistent dimensions. The supplier blames “material variations” or “complex geometry.” The real cause? Substandard tooling and outdated machining practices.

Why This Happens

To cut costs, many suppliers use handheld drills, unbalanced tool holders, and inferior cutting tools. These practices create vibration, poor surface finishes, and dimensional inconsistencies—especially on precision parts requiring tight tolerances.

The Red Flags to Watch For

- Surface roughness worse than Ra 3.2

- Visible tool marks or chatter patterns

- Inconsistent part-to-part quality

- Reluctance to discuss tooling specifications

Our Solution: Industrial-Grade Tooling Standards

We’ve eliminated this problem through our uncompromising tooling standards:

Our Tooling Protocol:

- Balanced Industrial-Grade Carbide Tools: No handheld drills, no bargain-basement tooling

- Precision Tool Holders: Balanced to ISO 1940-1 G2.5 or better

- Regular Tool Maintenance: Tools replaced before wear affects quality

- Advanced Machining Strategies: Optimized cutting parameters for each material

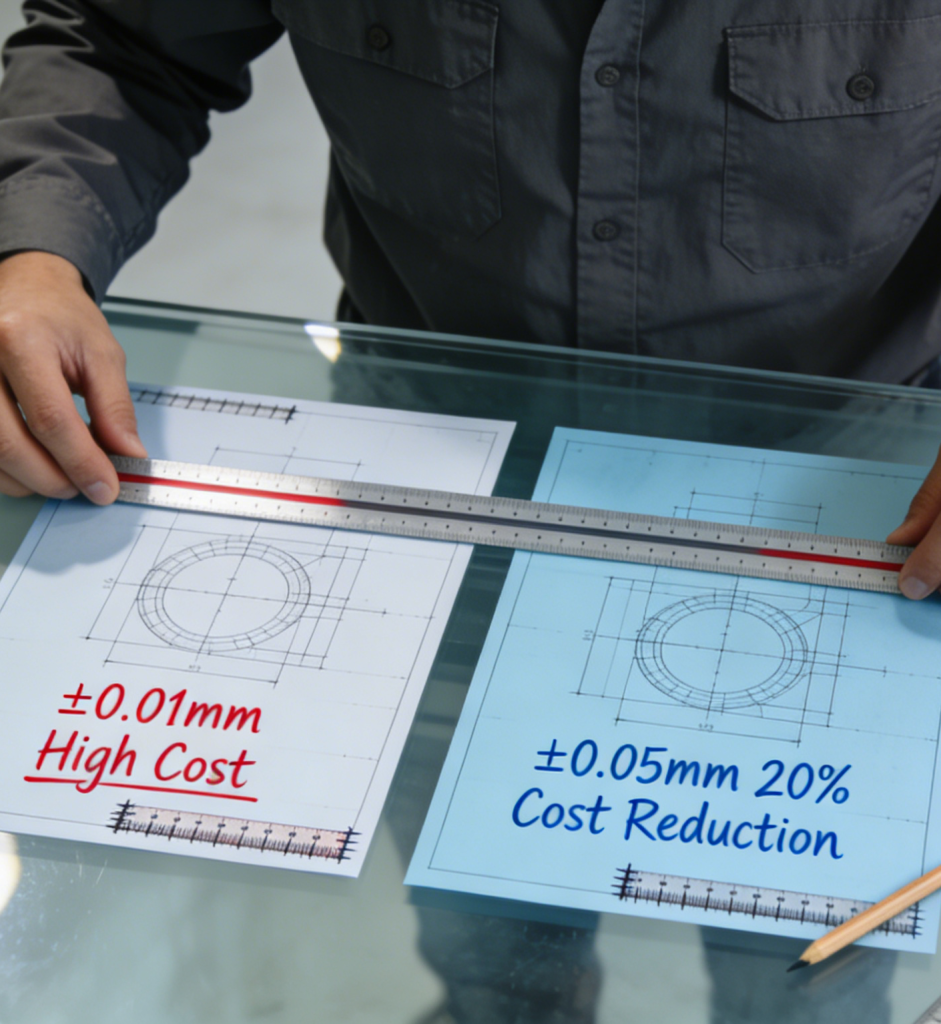

The Results We Guarantee:

- Surface Roughness: Ra 1.6 or better (standard), Ra 0.8 or better (precision)

- Dimensional Consistency: ±0.01mm or better on critical features

- Zero Tool Marks: Professional finishes on every part

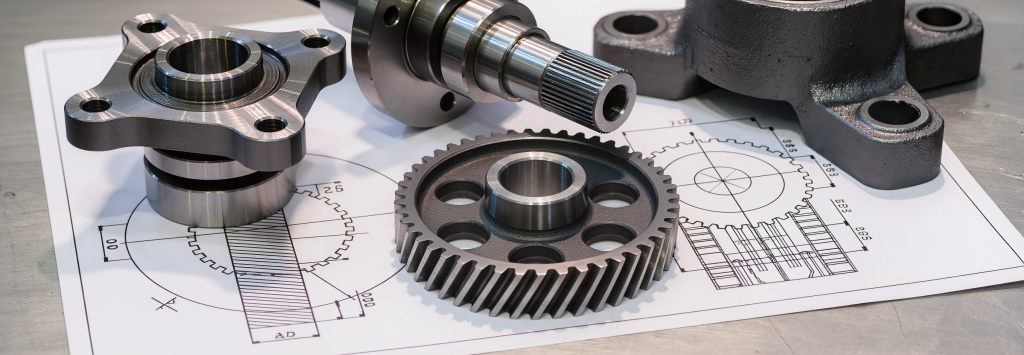

*Image of precision CNC machining operation showing balanced carbide cutting tool and professional workholding fixture*

Risk #4: The “Post-Delivery Deformation” Nightmare

The Problem

Your parts look perfect on the machine. They pass inspection. You receive them, approve them—and then days or weeks later, they’re warped, twisted, or bent. Material stress has been released, and your precision parts are now scrap.

Why This Happens

This is one of CNC machining’s most insidious problems, particularly with materials prone to internal stress:

- PVC and POM (Delrin): High internal stress from extrusion

- Thin-wall aluminum: Stress from rapid material removal

- Long shafts: Stress accumulation during machining

Many suppliers, chasing delivery schedules, skip critical stress-relief steps. Parts leave the factory “perfect,” but internal stresses continue to equalize—causing deformation after delivery.

The Red Flags to Watch For

- Parts that look perfect but warp shortly after receipt

- Supplier rushing delivery without explaining process steps

- No discussion of stress-relief protocols

- Focus on speed over process integrity

Our Solution: Stress-Relief Process Protocol

For stress-prone materials, we’ve implemented a proven three-stage process:

Stage 1: Rough Machining

- Remove 80-90% of material quickly

- Minimal precision requirements at this stage

- Create near-net shape

Stage 2: Stress Relief

- Parts rest for 24-72 hours (material-dependent)

- Optional heat treatment for aluminum alloys

- Internal stresses naturally equalize

Stage 3: Precision Finishing

- Final machining to exact tolerances

- Achieve required surface finish

- Parts are now dimensionally stable

The Result: Parts that stay true. No post-delivery surprises, no rework