Part 1: Understanding the Basics of Aerospace CNC Parts Surface Treatment

1.1 The Significance of Surface Treatment in Aerospace CNC Parts

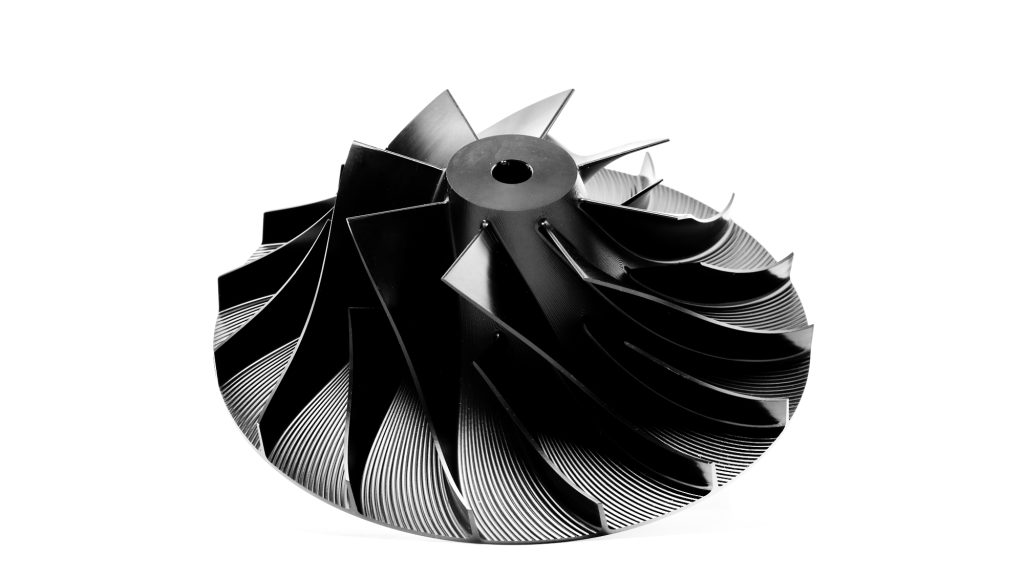

Surface treatment is a critical step in aerospace manufacturing, directly impacting component reliability and safety. For high-stress parts like turbine blades and landing gear, treatments such as vacuum nitriding enhance fatigue resistance by up to 40%, extending service life in extreme operational conditions . Smooth surface finishes from processes like sulfuric anodizing reduce aerodynamic drag by minimizing air turbulence, improving fuel efficiency for aircraft .

Regulatory compliance is equally vital. International standards such as ISO 8074 and ISO 8078 mandate surface treatments that meet strict corrosion resistance and environmental safety criteria . These standards, developed by organizations like China’s Aviation Industry Corporation and European partners, ensure uniformity in coating quality, particularly for aluminum and stainless steel parts used in critical systems .

1.2 Common Types of Surface Treatments for Aerospace CNC Parts

Anodizing is widely used for aluminum alloys, forming a porous oxide layer via sulfuric acid electrolysis. This process, specified in ISO 8078, provides excellent corrosion resistance and allows dyeing for part identification—critical for maintenance and assembly . The coating’s hardness (up to 300 HV) enhances wear resistance, while its dielectric properties make it suitable for electrical insulation .

Electroplating technologies have evolved with eco-friendly alternatives like Savroc’s TripleHard® trivalent chromium plating, which replaces toxic hexavalent chrome. This REACH-compliant coating achieves 900–1500 HV hardness, offering 17× longer service life than traditional chrome on hydraulic rods and landing gear components . Nickel plating, meanwhile, provides a smooth, corrosion-resistant finish ideal for parts exposed to lubricants and fuels.

Painting uses aerospace-grade formulations such as thermal barrier coatings and UV-resistant paints. Plasma Electrolytic Oxidation (PEO) offers a green alternative, forming ceramic coatings on aluminum that withstand thermal shocks from -196°C to 150°C—ideal for spacecraft thermal management . These coatings also improve corrosion resistance in saline environments, a key requirement for coastal or high-humidity operations .

1.3 Initial Considerations when Choosing Surface Treatment

The base material dictates viable treatments: aluminum alloys perform best with anodizing or PEO, leveraging their oxide layer formation . Titanium components often use chemical conversion coatings or anodizing to enhance adhesion for subsequent paint layers . Steel parts, particularly high-strength alloys in landing gear, benefit from vacuum nitriding to boost surface hardness without compromising core toughness .

Part 2: In-Depth Factors for Selecting the Right Surface Treatment

2.1 Operational Environment of the Part

Temperature and Humidity extremes demand tailored solutions. High-altitude, low-temperature zones require heat-resistant coatings like TiAlSiN (a PVD coating) that withstand oxidation up to 1150°C, protecting engine components from thermal fatigue . In tropical or coastal regions, where humidity exceeds 85%, PEO coatings on aluminum reduce galvanic corrosion in Al-CFRP joints by 90% compared to conventional anodizing .

Chemical Exposure to jet fuels, de-icing fluids (glycols), and lubricants necessitates chemical resistance. Fluoropolymer coatings repel hydrocarbon-based fuels, while trivalent chromium plating resists de-icing fluid erosion—critical for landing gear struts . For parts in contact with hydraulic fluids, nickel plating provides a non-reactive barrier that maintains performance over 10,000+ cycles.

2.2 Performance Requirements of the Part

Mechanical Performance needs vary by component. Landing gear, subjected to high impact loads, benefits from vacuum nitriding, which creates a 50–100μm hardened layer (500–1000 HV) while minimizing distortion . Engine turbine blades use BALORA™ PVD coatings, which combine oxidation resistance with abrasion protection to handle high-speed particle impacts .

Electrical Conductivity is essential for avionic components. Gold-plated surfaces on connectors ensure low resistance (≤0.01Ω) while resisting tarnish, while anodized aluminum can be selectively plated to create conductive paths without compromising corrosion resistance .

2.3 Cost-Benefit Analysis

Initial costs vary significantly: PVD coatings cost 30–50% more than anodizing but last 3–5× longer in high-wear applications . TripleHard® trivalent chromium plating reduces total lifecycle costs by 30–55% compared to hexavalent chrome, offsetting higher upfront expenses through lower maintenance and waste disposal fees . For large-batch components like fasteners, anodizing remains cost-effective due to its low material and energy requirements .

2.4 Compatibility with Manufacturing Processes

Heat-based treatments like vacuum nitriding (500–600°C) must follow rough machining to avoid dimensional shifts . Anodizing requires strict pre-cleaning to remove oils, as contaminants cause coating defects . PEO’s single-step process integrates seamlessly with CNC workflows but demands precise voltage control (≤292V for aluminum) to prevent part distortion .

FAQs

- Can a single surface treatment meet all requirements?

- Rarely. For example, aluminum hydraulic components often combine sulfuric anodizing (corrosion resistance) with a thin nickel plating (lubricity). Titanium fasteners may use chemical conversion coating (adhesion) followed by PEO (wear resistance) .

How does surface treatment affect weight?

Anodizing adds negligible weight (0.0001–0.001″ thickness), while thick chrome plating can increase part mass by 5–10% . PEO coatings, at 10–50μm, offer lightweight protection critical for fuel-efficient designs .

Are there eco-friendly options?

Yes. Trivalent chromium plating eliminates carcinogenic hexavalent chrome , while low-voltage PEO uses silicate electrolytes with minimal hazardous waste . Water-based aerospace paints meet REACH and RoHS standards, reducing volatile organic compound emissions .

LSI and NLP Keywords

LSI Keywords: Aerospace CNC part surface treatment selection, corrosion-resistant coatings for aerospace, PVD coating compatibility in aerospace manufacturing

NLP Keywords: Environmental factors in aerospace surface treatment, cost-benefit of trivalent chromium plating, thermal stability of PVD coatings

Related Vocabulary: Galvanic corrosion protection, vacuum nitriding, anodizing standards (ISO 8078), REACH compliance, thermal barrier coatings