Unmanned Aerial Vehicles (UAVs), commonly known as drones, are rapidly evolving in both recreational and commercial sectors. One of the most critical challenges in UAV engineering is weight optimization. The lighter the components, the better the drone’s performance, efficiency, and endurance. Among these components, CNC machined lightweight brackets play an essential role in mounting sensors, cameras, payload systems, and structural assemblies without adding unnecessary mass.

Why Lightweight CNC Brackets Matter in UAV Design

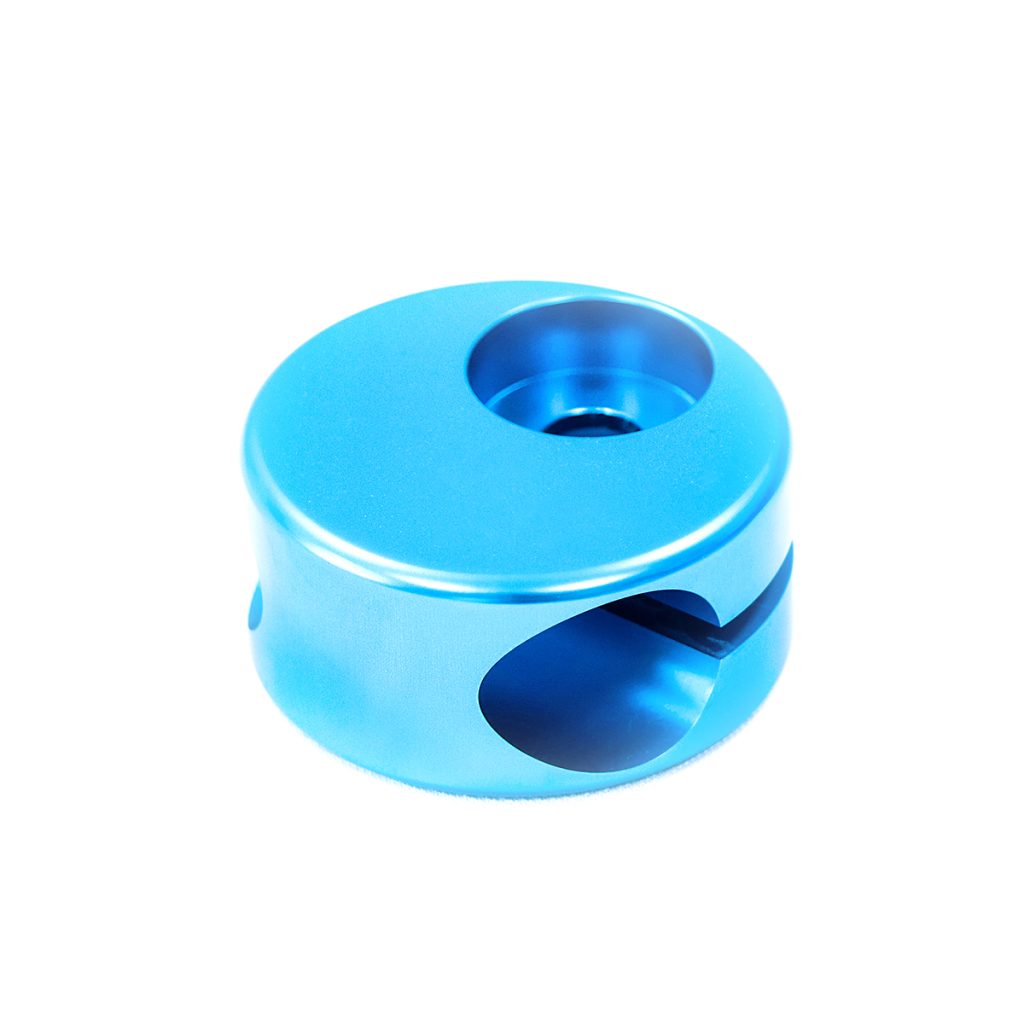

Lightweight CNC brackets are precision-engineered supports that help in securely attaching various parts of a UAV while keeping the total weight as low as possible. These brackets are often made from materials such as aluminum alloys, titanium, and carbon fiber composites. Reducing the weight of mounting hardware directly reduces the strain on the UAV’s propulsion system, allowing for longer flight times and higher payload capacity.

Material Selection for CNC Machined UAV Brackets

Aluminum Alloys (6061, 7075) – Known for excellent strength-to-weight ratios, corrosion resistance, and machinability.

Титан – Exceptional strength and corrosion resistance but higher cost and machining complexity.

Carbon Fiber Reinforced Polymer (CFRP) – Extremely light and strong, ideal for high-performance UAVs.

Magnesium Alloys – Ultra-lightweight but require careful handling to avoid corrosion.

Impact on Payload Strain

Payload strain occurs when the drone’s motors and propellers must work harder to lift the combined weight of the UAV’s frame, payload, and other components. Heavy mounting brackets increase this load, leading to reduced flight time, higher battery consumption, and potential overheating of motors. By using lightweight CNC brackets, UAV engineers can minimize this strain and extend operational efficiency.

Design Optimization Techniques

Topology Optimization – Removing unnecessary material while maintaining strength.

Finite Element Analysis (FEA) – Simulating stress distribution to refine bracket geometry.

Thin-Walled Designs – Reducing weight without sacrificing structural integrity.

Multi-Functional Integration – Combining multiple bracket functions into a single part.

Applications in Commercial UAVs

Aerial Photography Drones – Stable camera mounts without excessive weight.

Delivery Drones – Payload carriers that optimize carrying capacity.

Survey & Mapping Drones – Sensor mounts for LiDAR, thermal cameras, and multispectral imaging.

Engineering Case Studies: Real-World Impact

In practical UAV engineering, the effect of lightweight CNC brackets on reducing payload strain is clearly reflected. Take agricultural survey drones as an example. Traditional agricultural drones used steel brackets to mount multispectral cameras, with each bracket weighing about 150 grams. After switching to 7075 aluminum CNC brackets optimized by topology, the weight of each bracket is reduced to 65 grams. For a drone equipped with 4 such brackets, the total weight reduction is 340 grams. In actual operation, the flight time of the drone is extended by about 12 minutes, and the battery consumption rate is reduced by 18%. The load capacity of the drone is also increased, allowing it to carry a higher-precision sensor with a weight of 200 grams without affecting the flight performance.

Another case is in logistics delivery drones. The original titanium alloy brackets used to fix the cargo compartment had a total weight of 800 grams for the entire drone. By adopting carbon fiber reinforced polymer CNC brackets with thin-walled design, the total weight of the brackets is reduced to 320 grams. This weight reduction makes the drone’s motor load decrease significantly. During the delivery process, the motor temperature is reduced by an average of 10°C, the risk of motor overheating is greatly reduced, and the maintenance cycle of the motor is extended by 50%. At the same time, the drone can carry 480 grams more cargo under the same battery capacity, which effectively improves the delivery efficiency.

Technical Challenges and Solutions

Although lightweight CNC brackets have significant advantages in reducing UAV payload strain, there are also some technical challenges in the design and manufacturing process. One of the main challenges is ensuring the structural strength while reducing weight. In some high-vibration environments, such as when the drone is flying in strong winds, lightweight brackets may be prone to fatigue damage. To solve this problem, engineers use finite element analysis to simulate the vibration frequency and stress distribution of the brackets under various working conditions, and then optimize the bracket structure, such as adding reinforcing ribs in key stress areas, to improve the fatigue resistance of the brackets.

Another challenge is the machining accuracy of lightweight materials. For example, carbon fiber reinforced polymer materials are difficult to machine, and it is easy to produce defects such as delamination and burrs during the CNC machining process, which affects the structural performance of the brackets. To address this issue, manufacturers have developed special cutting tools and machining processes for carbon fiber materials. Using diamond-coated cutting tools and optimizing the cutting speed and feed rate can reduce the occurrence of machining defects. In addition, strict quality inspection after machining, such as ultrasonic testing, ensures that the brackets meet the design requirements.

Synergy with Other Weight-Reduction Measures

Lightweight CNC brackets do not work in isolation in reducing UAV payload strain; they can form a synergistic effect with other weight-reduction measures. For instance, when combined with lightweight batteries, the overall weight of the UAV is further reduced, and the payload strain is alleviated more effectively. The lightweight brackets reduce the weight of the structural components, while the lightweight batteries provide more efficient energy supply, enabling the drone to fly longer with the same payload.

The combination of lightweight CNC brackets and efficient motor systems is also beneficial. Efficient motors have higher energy conversion efficiency, and when paired with lightweight brackets, the overall energy consumption of the UAV is reduced. The reduced load on the motors allows them to operate in a more efficient range, further reducing battery consumption and extending flight time.

In addition, the integration of lightweight CNC brackets with the UAV’s overall structural optimization can achieve better weight-reduction results. By optimizing the layout of the brackets and integrating multiple functions into one bracket, the number of components is reduced, and the overall weight of the UAV is further decreased. For example, integrating the bracket for mounting the camera and the bracket for fixing the GPS module into a single multi-functional bracket not only reduces the number of brackets but also simplifies the assembly process, which is conducive to reducing the overall weight of the UAV.

Future Trends in Lightweight CNC Brackets for UAVs

With the continuous development of UAV technology, lightweight CNC brackets are also facing new development trends. One of the trends is the application of new materials. Graphene-reinforced composites are being studied and applied in the manufacturing of CNC brackets. Graphene has excellent mechanical properties and light weight, which can further improve the strength-to-weight ratio of the brackets. It is expected that in the next few years, graphene-reinforced composite brackets will be widely used in high-performance UAVs, bringing a new breakthrough in reducing payload strain.

Another trend is the application of artificial intelligence in the design of lightweight CNC brackets. By using AI algorithms to analyze a large amount of data on bracket performance, AI can automatically generate optimal bracket designs that meet the requirements of lightweight and high strength. This not only improves the design efficiency but also can find design schemes that are difficult to be discovered by traditional design methods, further optimizing the performance of the brackets.

In addition, additive manufacturing technology is gradually combined with CNC machining in the production of lightweight brackets. Additive manufacturing can realize complex structures that are difficult to be machined by traditional CNC methods, which is conducive to further optimizing the structure of the brackets for weight reduction. The combination of additive manufacturing and CNC machining can give full play to the advantages of both technologies, improving the manufacturing accuracy and performance of the brackets.