Automated deburring and finishing are essential processes in modern manufacturing. Traditionally, CNC machines have handled these operations with precision, but industrial robots and cobots are quickly reshaping the landscape. This article explores the advantages and trade-offs of CNC machining versus robotic solutions in deburring and finishing applications.

1. The Rise of Robotics in Manufacturing

The global industrial robotics market is expected to grow significantly over the coming years. Robots are becoming more cost-effective, flexible, and efficient, making them an attractive option for deburring and finishing tasks.

[Illustration: Chart showing growth in robotics market]

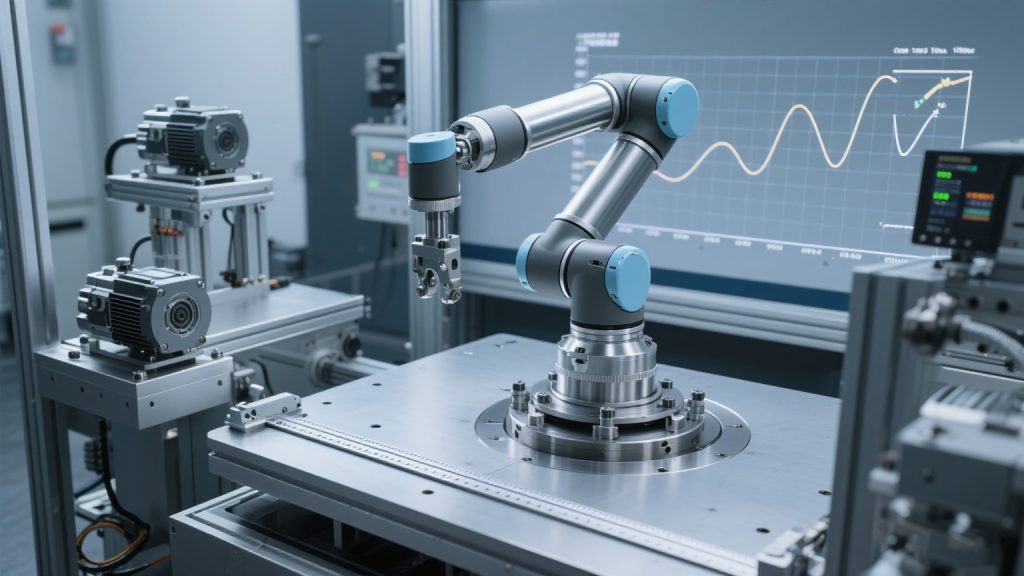

2. What Robotic Deburring Looks Like

Robotic arms—especially when paired with advanced tools like ceramic fiber brushes—offer repeatable, precise deburring and finishing. They can manipulate both tools and parts, handle complex geometries, and reduce human involvement.

[Illustration: Diagram of robotic deburring cell]

3. CNC vs. Robotics: Key Comparisons

High-Touch vs. Plug-and-Play

CNC machines require operators, part handling, and careful programming. Robots, once programmed, can execute tasks with minimal intervention.

Fixed vs. Flexible

CNCs hold parts stationary while tools work around them. Robots can reorient both tools and parts, offering flexibility for intricate designs.

Accuracy vs. Repeatability

CNC machines excel at precision, while robots provide consistency and repeatability. Both can achieve high-quality finishes when properly applied.

[Illustration: Table comparing CNC vs. Robotics]

4. How Robotics Complement CNC Systems

Instead of replacing CNC machines, robots often complement them by handling loading/unloading, tool changes, or post-processing tasks. This maximizes uptime and throughput.

[Illustration: Flow diagram of CNC + Robot integration]

5. Industry Applications

Robotic and CNC deburring solutions are widely used across industries:

– Automotive: Engine components, gears, and transmissions.

– Aerospace: Complex alloy components.

– Medical: Stainless steel and titanium devices.

– General Fabrication: Plastics, composites, ceramics, and sheet metals.

[Illustration: Industry icons grid]

6. Cobots: Small but Powerful

Collaborative robots (cobots) are particularly suited for small shops and mixed production environments. They can be quickly reprogrammed, making them ideal for low-volume, high-mix operations.

[Illustration: Operator working with cobot]

7. Lights-Out Manufacturing

With robotics, manufacturers can achieve 24/7 production with minimal supervision. This reduces labor costs, increases consistency, and enables true lights-out manufacturing.

[Illustration: Factory running lights-out with robots]

Cobots vs. CNC: The Future of Deburring and Finishing for Small Shops

Small and medium-sized manufacturers face unique challenges in deburring and finishing operations. Limited floor space, high-mix production, and workforce constraints make it difficult to rely solely on traditional CNC systems. Collaborative robots, or cobots, are emerging as a powerful alternative. This article explores how cobots compare with CNC systems, highlighting their strengths and limitations.

1. What Makes robots Different?

Cobots are designed to work safely alongside humans. Unlike traditional industrial robots, they don’t require large cages or complex safety systems. They’re lightweight, easy to program, and can quickly adapt to new tasks. This makes them highly suitable for smaller shops.

[Illustration: Operator collaborating with a cobot on a workbench]

2. Deburring and Finishing with robots

When equipped with advanced finishing tools, cobots can handle a wide range of materials—metals, plastics, composites, and ceramics. Their repeatability ensures consistent results, and they can often combine deburring and surface finishing in one step.

[Illustration: Cobot using a brush on a metal component]

3. CNC vs. robot: A Side-by-Side Look

Cost and Accessibility

CNC machines require high upfront investment and skilled operators. Cobots, in contrast, have lower costs and are easier to set up.

Flexibility and Space

CNCs are fixed systems with large footprints. Cobots are compact and mobile, fitting into smaller shops and flexible layouts.

Precision vs. Adaptability

CNC excels at micrometer-level accuracy. Cobots trade some precision for flexibility, adaptability, and quick changeovers.

[Illustration: Comparison table: CNC vs. Cobot traits]

4. Industry Use Cases

Cobots are already proving their value across industries:

– Job Shops: Quickly adapting to diverse part runs.

– Medical: Handling delicate titanium and stainless parts.

– Aerospace: Assisting in finishing complex geometries.

– Electronics: Working with plastics and composites safely.

[Illustration: Icons representing industries]

5. When to Choose Cobots Over CNC

Cobots are ideal for:

– Shops with frequent changeovers.

– Limited floorspace environments.

– Applications requiring operator collaboration.

– Businesses seeking lower cost of entry into automation.

[Illustration: Small workshop with cobot in use]

6. Hybrid Workflows: Cobots + CNC

The best results often come from combining both technologies. Cobots can take over repetitive deburring and finishing, while CNC machines handle the high-precision cuts. This hybrid workflow ensures maximum efficiency and quality.

[Illustration: Workflow diagram showing cobot + CNC integration]

Hybrid CNC + Robotics Systems: The Best of Both Worlds in Deburring and Finishing

Manufacturers no longer need to choose strictly between CNC machines and robotic automation. A hybrid approach that integrates both technologies offers unmatched advantages for deburring and finishing operations. By combining CNC precision with robotic flexibility, shops can achieve superior results, improved efficiency, and higher return on investment.

1. Why Hybrid Systems?

While CNC machines excel in accuracy and rigidity, they can be limited in flexibility and workflow efficiency. Robots, on the other hand, bring adaptability, automation, and the ability to handle part transfers and finishing tasks. A hybrid setup ensures both strengths are leveraged without compromise.

[Illustration: Diagram showing CNC machine connected to robotic arm cell]

2. How Hybrid Workflows Operate

A typical hybrid workflow might involve a CNC machine performing high-precision machining, followed by a robotic arm automatically removing the part, deburring edges, and applying surface finishing tools. This reduces downtime, eliminates extra handling, and allows continuous production.

[Illustration: Workflow diagram – CNC machining → robot deburring → finished part]

3. Benefits of CNC + Robotics Integration

– Maximized CNC Uptime: Robots take over secondary processes so CNCs can focus on machining.

– Reduced Labor Needs: Fewer operator touches lower injury risk and scrap.

– High Precision and Consistency: CNC ensures accuracy, while robots guarantee repeatability.

– Compact Footprint: Robotic cells can be integrated without consuming excessive space.

– Scalability: Systems can expand with production growth.

[Illustration: Side-by-side chart of CNC-only vs. CNC + Robotics efficiency]

4. Industry Applications of Hybrid Systems

– Automotive: Engine components, gears, and drivetrains with high production volumes.

– Aerospace: Lightweight alloys requiring tight tolerances and finishing.

– Medical: Precision implants and surgical instruments.

– General Fabrication: Sheet metals, plastics, and composites processed at scale.

[Illustration: Industry grid showing auto, aerospace, medical, fabrication]

5. Challenges and Considerations

Hybrid systems require careful planning. Integration between CNC and robotic systems can involve complex programming, safety considerations, and investment in tool compatibility. However, with the right integrators and advanced deburring tools, these challenges are easily managed.

[Illustration: Engineer overseeing hybrid integration]

6. Realizing Lights-Out Manufacturing

Hybrid systems open the door to true lights-out manufacturing. Robots can keep CNC machines supplied with parts, handle deburring, and finish components around the clock. This reduces labor costs, minimizes downtime, and ensures continuous productivity.

[Illustration: Factory floor with CNC machines and robots operating unattended]