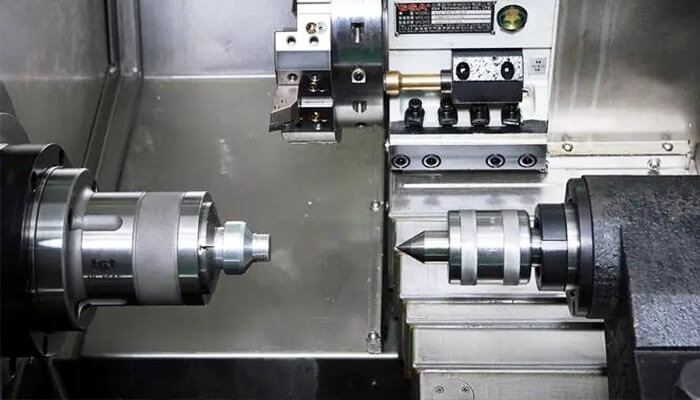

The structural characteristics of the sleeve parts are that the wall thickness of the holes is thin, and the thin-walled parts are often clamped during the machining process. Deformation caused by the influence of cutting force and thermal deformation. In this regard, BEST PARTS has summarized some process measures to prevent deformation of parts:

How to prevent deformation of precision CNC machining sleeve parts

(1) The coarse and fine machining are separately performed to reduce the influence of cutting force and cutting heat, so that the deformation of the sleeve parts produced by the rough CNC lathe machining can be corrected in the finishing process.

(2) Reducing the influence of clamping force The following measures are taken in the process to reduce the influence of clamping force:

1 When precision CNC machining adopts radial clamping, the clamping force should not be concentrated on a certain radial section of the workpiece, but should be distributed over a large area to reduce the clamp on the unit area of the workpiece. Tight force. If the workpiece can be mounted in an open ring of suitable thickness, it is clamped together with the ring. Special jaws that increase the contact area can also be used. When positioning the hole, an open mandrel clamp should be used.

2 The position of the clamping force should be selected in the part with strong rigidity of the part to improve the deformation of the thin-walled part under the clamping force.

3 Change the direction of the clamping force and change the radial clamping to the axial clamping.

4 Precision CNC machining produces rigid rigid process bosses or process threads on the workpiece to reduce clamping deformation. It is clamped with special structure jaws during machining, and the flange is cut off at the end of machining.

(3) Reduce the influence of cutting force on deformation:

1 Increase the tool lead angle and the main rake angle to make the cutting edge sharper during machining and reduce the radial cutting force.

2 Separate the coarse and fine machining so that the deformation of the sleeve parts produced by roughing can be corrected in the finishing process and take a smaller amount of cutting.

3 The inner and outer round surfaces are machined at the same time to offset the cutting force.

The arrangement of heat treatment between roughing and finishing can reduce the influence of heat treatment deformation. After heat treatment, the sleeve parts will generally produce large deformation, which can be corrected during finishing, but pay attention to appropriately increase the allowance of finishing. .